Technology and innovation play an important role in achieving sustainable growth and impacting competitiveness. Today, mineral and metal industry across the globe is facing a serious economic crisis due to continuous fall in commodity prices, depleting raw material sources, non-availability of high grade ores, stringent environmental rules and societal expectations. In the era of declining prices clubbed with weak demand, the new tax regime in the mining sector in India in the form of District Mineral Fund (DMF) or National Mineral Exploration Fund (NMEF) may pose additional threats for the survival of the already ailing mineral and metal industry. This necessitates the need for continuous improvement in the technology as well as developing disruptive technologies or adopting the state of the art technologies in every facet of the metal business. This will also help companies to show their commitment towards environment and societal issues to ensure securing social license to operate.

There is an urgent need to provide a creative culture across mineral and metal industry to support the generation of new ideas and its diffusion into products, processes and services with focus on:

- Encouraging research and development for environmental friendly technologies & systems

- Augmenting technical skills

- Enabling access to expertise

- Strengthening system-wide capabilities and exploiting complementarities

- Improving frameworks for innovation, including regulation and standards

- Facilitating collaboration through exchange and dialogue about innovation

The most important factor from a commodity market point of view is that technology-driven cost reductions would help drive prices lower on a structural basis and keep prices low for an extended period.

Need of Advanced Technology in Mining

Mining is a significant sector of the Indian economy, endowed with metallic and non-metallic minerals. India produces 89 minerals including 4 fuel minerals, 48 non-metallic minerals, 10 metallic minerals, 3 atomic minerals, and 24 minor minerals. However, the public expenditure on exploration in India is negligible when compared to other countries and is less than 1% of total world expenditure on exploration in comparison to Australia, Africa and Canada incurring between 13-18%. As surface based resources are getting depleted continuously, focus may have to be shifted to deep seated resources i.e underground which shall require deep earth survey. India despite having similar geological formation like that of South Africa and Australia is lacking in innovations in mining technology.

The process of industrialization should encompass with its fold an approach of development with an eco-human countenance i.e any development initiative should have provisions to accommodate within its jurisdiction, the concerns of the local people and ecology. As the issues in mining and downstream industries i.e beneficiation, processing, refinery, smelting, etc in non-ferrous industries are alike , technological intervention can easily mitigate all risks and can help in bringing down the operating cost for sustainable business.

Technological Intervention in Aluminium and other Non-Ferrous Industry

The discovery of more than 3 billion metric tons of proven gibbsitic bauxite reserves and more than 250 billion tons of coal reserves has put India on world aluminium map as the most preferred location for setting up the Integrated Aluminium Complexes. Although, India is ranked globally at 5th position in terms of Bauxite reserves, but its contribution in the world aluminium production is negligible and less than 3% of the world production. Looking into present challenges of land, environment, water, energy and the fact that nonferrous metal industry produces large wastes, it appears that zero discharge, zero waste may be the only solution in the interest of industry as well as country. Innovation is a critical component and it should not be forgotten that Innovation is more radical and transformational than simply improvement. Thus, radical changes are need in the mining and metallurgical sector. Some of the innovative solutions/ technologies which can be adopted or need development are:

- Fly Ash Mining to recover unburnt carbon and for production of Alumina/ Aluminium feed for glass industry etc

- Use of cement free Geo-Polymer based green concrete to replace cement with fly ash and also converting other wastes like tailings and slags into Geo-polymer

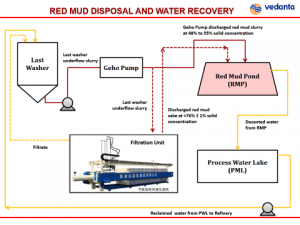

- Use of Red Mud for recovery of Iron, Titanium or use of Red Mud as de-sulpharizing agent in cement industry

- Use of plasma/ microwave/ ultra-high temperature gasification for converting all hazardous wastes like spent pot lining, anode butt, rubber, fume treatment plant bags, filter bags, rubber, used conveyors etc for converting into electricity or syn gas

- Use of nano technology for treatment of waste water , mining water as a replacement of expensive RO , Ion exchange etc to ensure zero reject and achieve zero liquid discharge

- Use of nano technology for metal recoveries as well as converting stack gases into methane, low cost oxygen plants as well improving combustion in Boilers to control SOx and NOx besides improving specific coal consumption etc

- Recovery of minor metals like Tellurium, Thallium, Vanadium, Gallium, Titanium, Cadmium, Arsenic etc in Aluminium, Copper, Lead –Zinc industry

- Advanced Mineral Beneficiation like removal of reactive silica from Bauxite and thus allowing use of low grade ores

Fly Ash Management

Most of the nonferrous metal industries have their own captive power plants to meet the requirement of steam and power for the extraction of metals. The disposal of fly ash and its utilization has become a major challenge due to fly ash notification issued by MOEF making 100% utilization of fly ash mandatory. The cement industry is the largest user of fly ash but for the mineral and metal industries located away from the cement industries, utilization becomes difficult due to logistics issues. In such areas fly ash bricks and land filling are the only options available.

On the other hand, Indian fly ash is regarded as one of the best raw material for making Alumino –Silicon cement or Geo-Polymer due to presence of high alumina and silica. Thus, Geo-polymer concrete represents an innovative solution that does not need the presence of portland cement as a binder. In contrast to portland cement, most Geo-polymer systems rely on minimally processed natural materials or industrial by products to provide the binding agents. The potential energy and carbon dioxide savings through the use of Geo-polymer can be considerable besides following benefits:

- Superior mechanical properties

- Chemical resistance (acids, toxic waste, salty water)

- Fire resistance & thermal insulation

- Short time to gain maximum strength

- Good abrasion resistance

- Reduction in cost of concrete from 10% to 20%

- 80% reduction in CO2 emissions

- Environment Friendly

- Wide span of applications

- Increased utilisation of industrial waste

Thus, use of fly ash as a replacement of cement can effectively contribute in fulfilling UN mission’s to avert climate change as nearly 1 ton of CO2 is generated for each ton of cement produced . Some of the countries like China, USA, and Australia are considering even manufacturing of Aluminium directly from fly ash using acidic route. Keystone USA has made claims of making Aluminium directly from fly ash. The focus on such disruptive technologies may help reducing electricity consumption in Aluminium industry to just 50%, reducing from 14,000 units to less than 7000 units per ton.

Environment Management System

It is possible to achieve Zero Discharge and Zero Waste in all the mining and mineral based industries by establishing effective environmental management systems which can help in complying with the regulatory requirements besides responding to public scrutiny and minimizing cost for waste treatment and disposal. Once the mining and mineral based industries are in a position to win the confidence of public by showing their sincerity towards environmental and waste management, real boost to industrialization process can be made.Experience has shown that all attempts to change the processes and production methods which reduce/prevent wastes and efficient use of resources ultimately result not only in environmentally sound practices but also in better business returns.

Conclusion

While commanding and emerging economies across the globe engage themselves in the unrelenting pursuit of swift economic advancement which will not only help them attain regional and global supremacy but will also help its citizenry in meeting their boundless desire for material wellbeing. The debate in the 21st Century has shifted from Industry propelled development (only) to environmentally responsible growth. While the earlier phenomenon was laid on a foundation characterized by ruthless pursuit for satiating the acquisitive urge of man which hardly possessed any concerns for the local ecology, the recent trends of discussion have designated a special standing for environment and allied issues and thus technology and innovation become the most critical area to drive down costs and thereby boost profitability rather than continuing with conventional approach.

(Dr Mukesh Kumar is the President & Group Head – Technology & Innovation, Vedanta Limited. He is looking after Technology/ Projects of Vedanta Resources, developing innovative culture in the group with a focus on Zero Discharge, Zero Waste and Zero Harm through implementation of state of the art technologies for optimum utilization of natural resources.)

Very informative article giving realistic direction to research & development for future of mineral industry.