GlassPoint is helping to decarbonise the aluminium sector by using solar energy to generate steam, delivering a cost-effective and reliable solution for industry leaders. Tailored to meet the demands of industrial users, particularly those in challenging remote environments, GlassPoint’s enclosed trough technology has seen successful deployment in large-scale projects across California and the Middle East. It’s the only industrial solar thermal solution proven at scale and is the most cost-effective solution of its kind to help industrial leaders achieve pressing net zero commitments.

We delve into the company’s initiatives in decarbonising the aluminium sector and highlight the tangible impact — including the company’s memorandum of understanding with Ma’aden to build the world’s largest industrial solar thermal facility to decarbonise the aluminium supply chain.

________________________________________________________

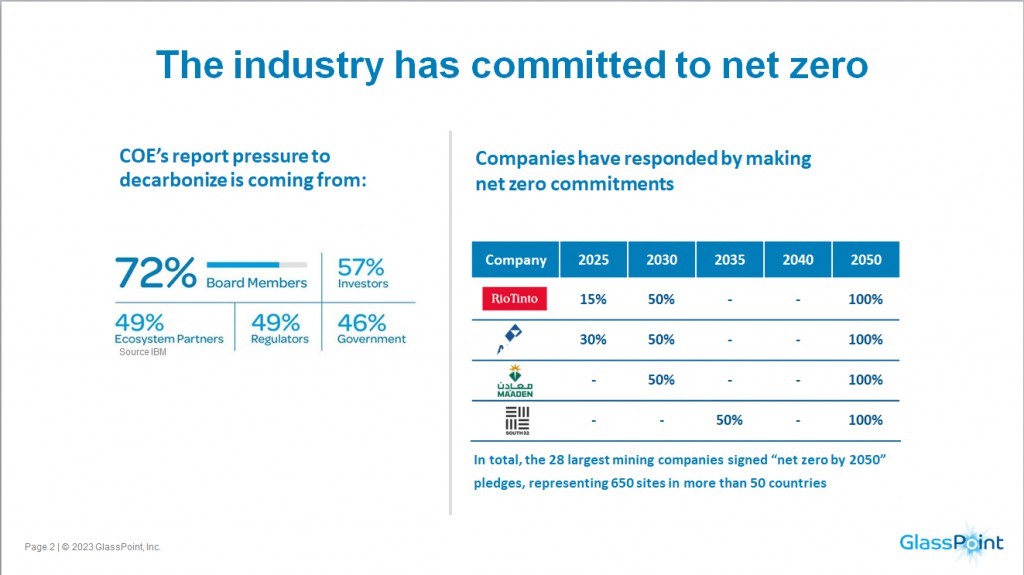

Many of the world’s largest companies have made ambitious net-zero commitments by which they’ve pledged to eliminate emissions from their business in the next few decades. As of 2023, 28 of the largest mining companies have pledged to be net-zero by 2050 – representing 650 mining sites in over 50 countries.

To meet these goals, businesses must completely decarbonise all operations, including industrial process heat – which makes up 26 per cent of all energy use.

Decarbonisation requires switching to renewable power and reducing emissions associated with burning fuel for steam. There are several ways to embrace renewables, with solar thermal technologies—as distinct from traditional photovoltaic solutions—providing the most compelling solution.

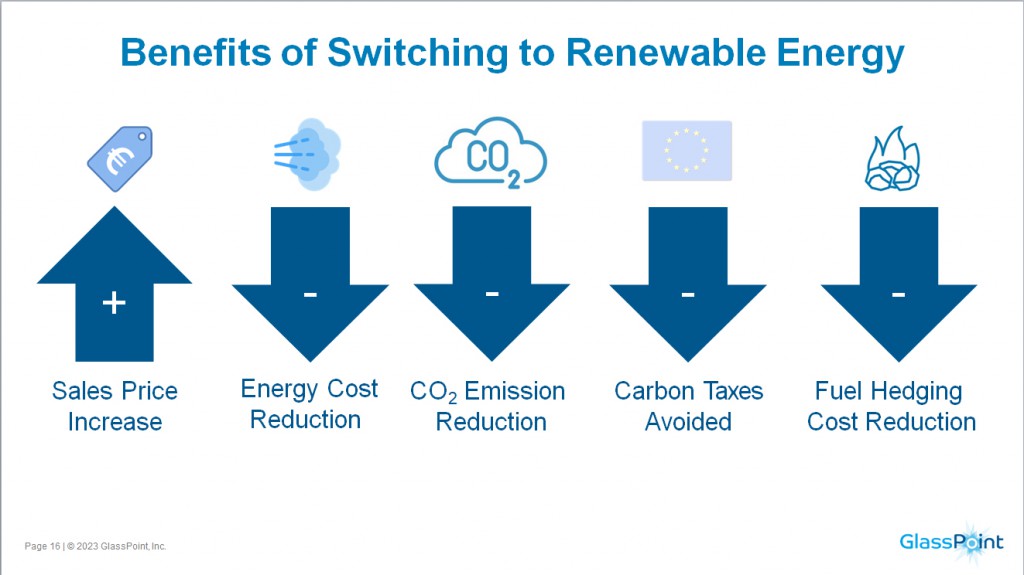

Solar thermal energy provides a range of benefits. It often reduces costs compared to existing fuel and always reduces emissions immediately, which in turn reduces exposure to carbon taxes and fuel price fluctuations. Solar-powered heat is also far less expensive than electrification or traditional photovoltaic solar systems.

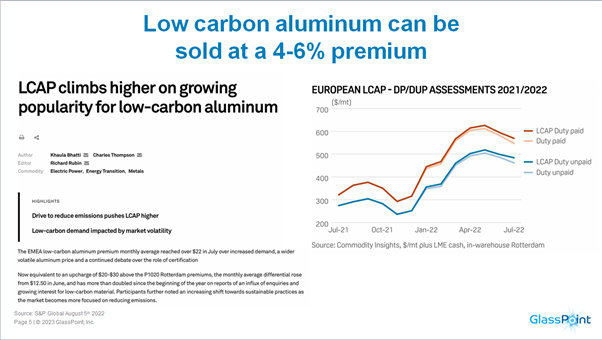

Moreover, low-carbon materials increasingly command a premium with manufacturers seeking to reduce emissions across their supply chain, hit net-zero commitments and earn the business of sustainability-minded consumers.

Early producers of low-carbon aluminium are seeing high demand and meaningful revenue increases, setting the stage to present low-carbon aluminium as a premium product with a strong market for the long term.

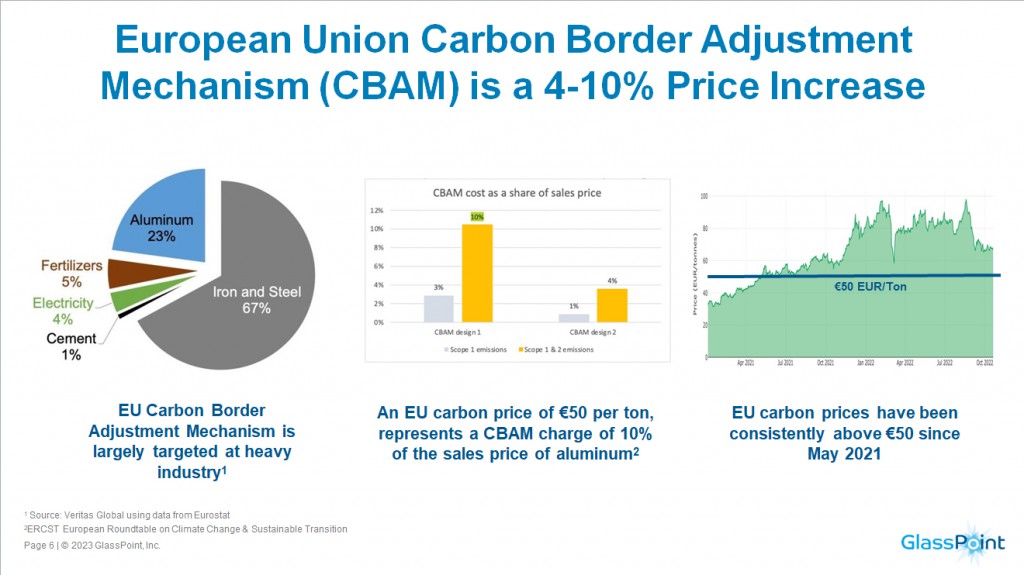

New tariffs and carbon pricing plans are directly driving up costs for traditional materials in the EU, and we can expect more to come globally in the wake of COP28 as governments race to meet commitments for tripling renewables by 2030 and transitioning away from fossil fuels. Solar thermal can significantly mitigate these expenses.

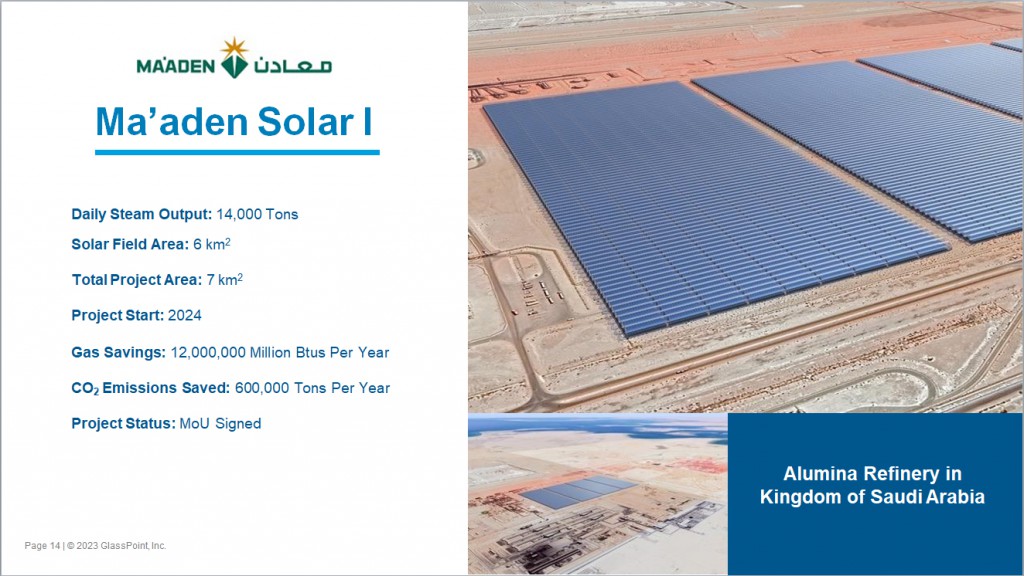

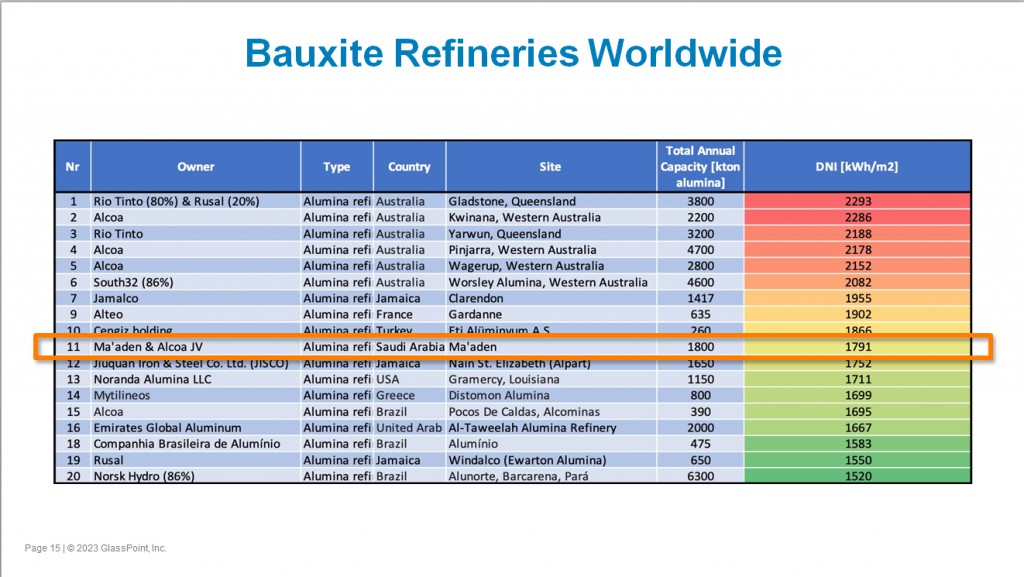

In 2022, GlassPoint signed an MOU with Ma’aden, Saudi Arabia’s mining champion and one of the fastest-growing mining companies in the world, to build the largest industrial solar thermal project in the world.

When complete, the facility will help Ma’aden achieve sustainability goals by reducing carbon emissions by over 600,000 tons annually while saving 12,000,000 mmBTUs of gas. This represents more than a 50 per cent reduction of carbon footprint in Ma’aden’s alumina refinery and 4 per cent of Ma’aden’s overall carbon footprint.

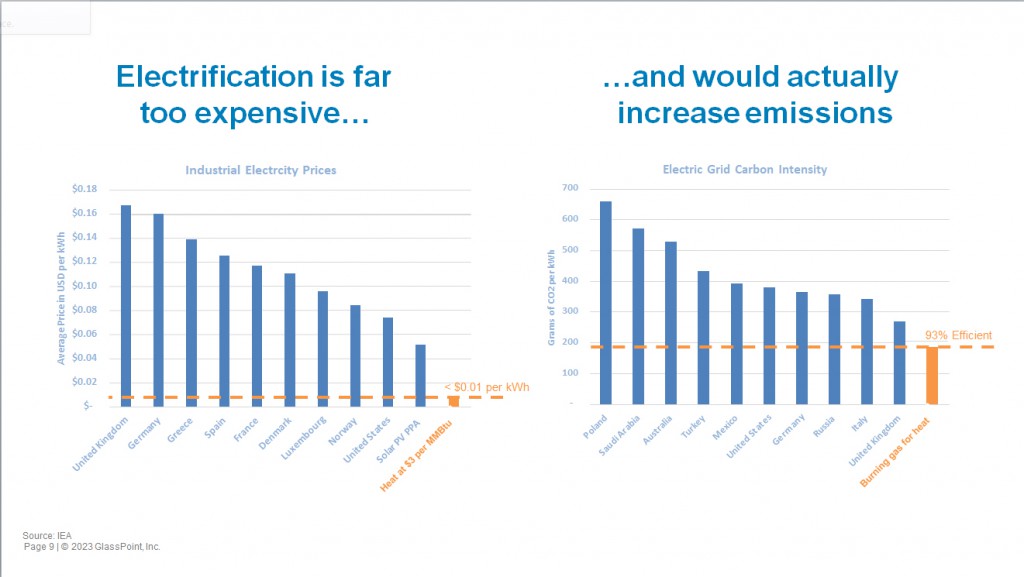

In recent years, a top solution to decarbonisation has been simply to electrify everything. Eventually, the thinking goes, the grid will go green, eliminating emissions. However, this logic doesn’t work with today’s industrial applications. Electrification is simply too expensive—at least six times more so, and in many cases as much as ten times more—and would substantially increase emissions until the grid is actually decarbonised decades from now.

GlassPoint is the only solution proven at scale to reduce carbon emissions from industrial process heat. The company has built more than half of the industrial solar steam capacity in the world, including a 340MWth plant that operates reliably today in Oman.

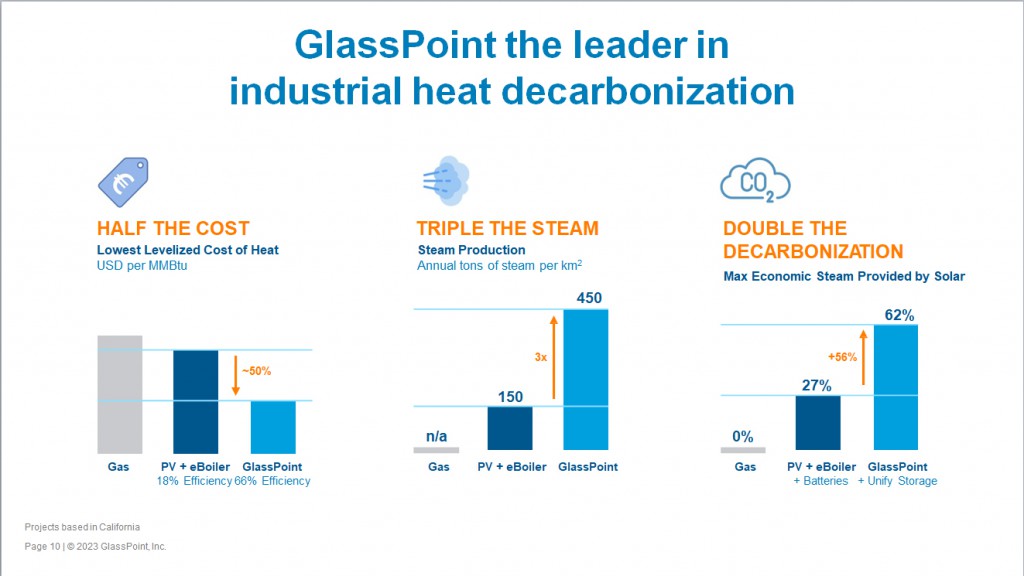

GlassPoint systems are by far the most compelling solution to deliver industrial heat. They are half the cost of a photovoltaic system with an electric boiler and more than three times more efficient. They can produce triple the steam as PV on the same amount of land, and, when paired with GlassPoint’s Unify storage system, double the rate of decarbonisation compared to PV plus batteries. Legacy fuels such as gas are more than twice as expensive and of course offer no decarbonisation.

In the past few months, GlassPoint has unveiled a range of technology enhancements that have driven down costs more than 30 per cent.

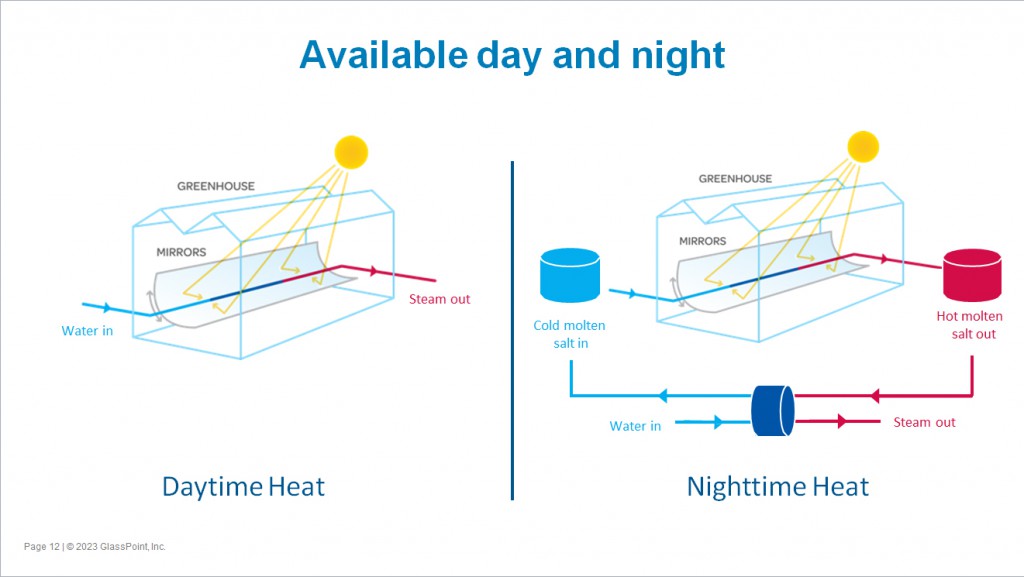

GlassPoint’s Unify storage system runs ternary molten salts under direct heat to deliver steam reliably both day and night, essential for modern industry.

The design eliminates the need for costly heat exchangers, oil handlers and oil itself, which is common to many solar thermal storage solutions, further improving economics. GlassPoint solutions can also flexibly integrate with gas and other solutions as needed.

In January 2024, GlassPoint and Ma’aden announced the first phase of project development for the world’s largest industrial solar thermal project. The showcase will have the capacity to supply nine tons of steam per hour to begin decarbonising Ma’aden’s alumina supply chain.

Initial capacity will be about 1 per cent of the larger project, which is slated to save more than 12M MMBTUs of energy annually and reduce carbon emissions by 600,000 tons per year. GlassPoint has also partnered with the Kingdom of Saudi Arabia to build a solar technology factory to supply the Ma’aden facility as well as additional projects in the region.

GlassPoint’s project with Ma’aden is the first step in decarbonising the $444B industrial heat market. The newly announced Technology Showcase will help educate and inspire industrial leaders in the region to harness solar thermal to decarbonise. GlassPoint has a strong project pipeline with more than 40 projects with a value of more than $12B under development.

As aluminium companies increasingly face pressing net-zero goals, decarbonising industrial process heat will be essential in making meaningful change. GlassPoint draws on its experience delivering the only industrial solar thermal solution proven at scale to continue to provide solutions that reduce costs and emissions while delivering reliability.