Projects serve as the backbone of progress, fuelling innovation and securing a competitive edge in ever-evolving industries. They act as catalysts for exploring emerging technologies, refining processes, and crafting solutions that meet the demands of a dynamic market. In this landscape, the aluminium packaging industry shines as a beacon of adaptability, consistently transforming to address consumer preferences and environmental imperatives.

With its exceptional blend of lightness, strength, recyclability, and protective capabilities, aluminium has emerged as the preferred material for packaging solutions across diverse sectors. Projects within this realm are instrumental in driving breakthroughs that champion sustainability, elevate efficiency, and redefine design possibilities. From crafting innovative materials to pioneering eco-friendly production technologies, these initiatives cater to the surging demand for high-performance and planet-friendly packaging. Whether it involves enhancing aluminium’s recyclability, improving manufacturing efficiency, or mitigating environmental footprints, these endeavours align seamlessly with global sustainability goals.

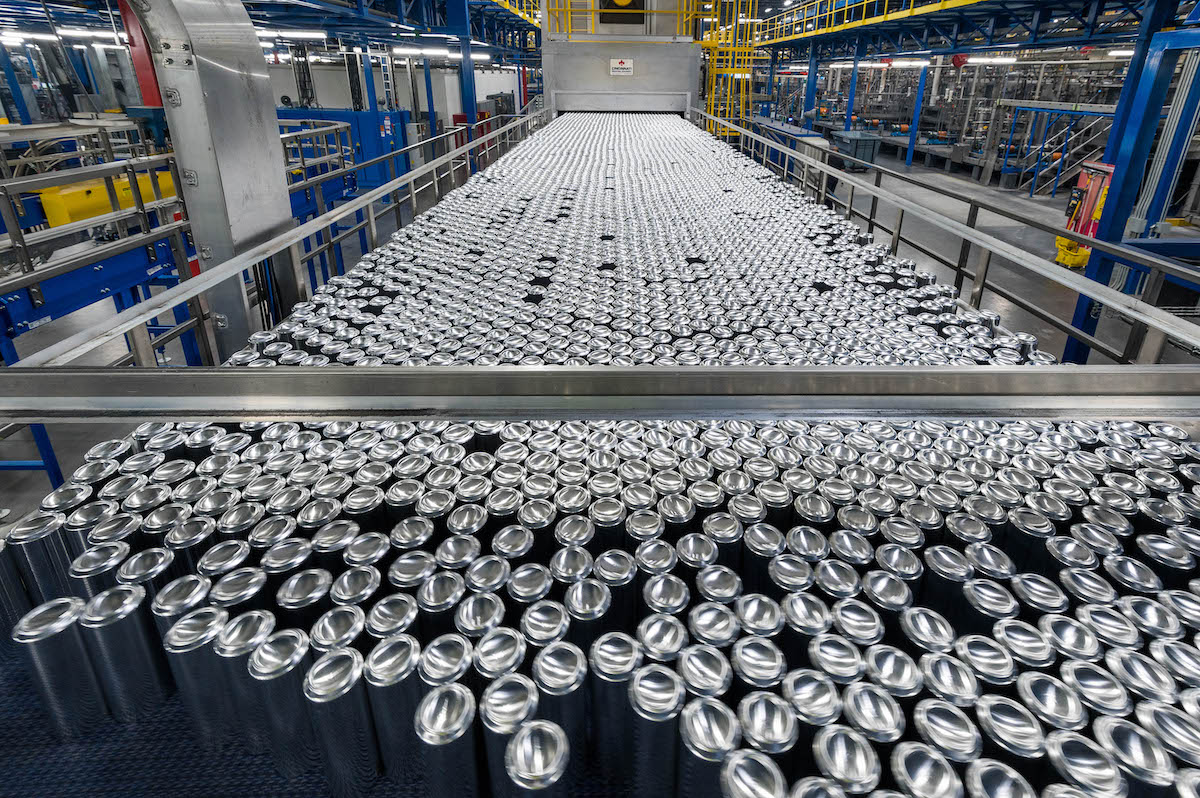

According to AL Circle’s report, ‘Aluminium in packaging: Consumer Trends & Market Dynamics,’ the aluminium packaging industry saw consistent growth in 2023, spurred by rising demand for beverage cans and packaging foils. With more than 11.5 million tonnes of aluminium flat-rolled products consumed in packaging applications throughout the year, the sector’s expansion was largely driven by a shift from conventional materials such as plastic and glass.

Commenced projects for 2024 – New aluminium bottling facility in Leicester

The Sustainable Bottling Company Limited, the producer behind Gunna’s soft drinks, launched a new aluminium bottling facility near Leicester, in England’s East Midlands region. Touted as the first of its kind in the UK and Europe, the newly launched facility is designed to bottle Gunna’s beverages into 470ml aluminium bottles, with additional sizes such as 330ml and 750ml also available. In addition to packaging Gunna’s drinks, the plant will offer white-label aluminium bottling services to other beverage brands. The project, which involved a £1 million investment raised by Gunna’s current investors, was inspired by the growing aluminium bottle market in the US and brands like PepsiCo, which introduced spring water in aluminium bottles under the Proud Source label.

Amcor Capsules’ Granby production plant

Amcor Capsules, a leader in producing premium closures for the wine and spirits industry, unveiled its latest achievement: a cutting-edge facility in Granby, Quebec. This new plant highlighted Amcor’s unwavering commitment to excellence and sustainability within the aluminium sector. With over three decades of experience in North America, Amcor Capsules’ expansion is a testament to its growth and dedication to its customers. Located just a short distance from its existing St. Cesaire site, the Granby plant marks a new chapter in providing localised solutions designed to enhance customer satisfaction to exceptional levels. In addition to its strategic location, the Granby plant symbolises operational efficiency and exceptional service. Its prime placement strengthens the supply chain, enabling faster distribution across North America while reducing lead times. This seamless integration reflects Amcor’s steadfast dedication to delivering excellence and perfection at every stage.

Can-One USA’s new facility

Can-One USA, a subsidiary of the Malaysia-based can manufacturing company Can-One, has officially begun operations at its new facility in the United States. Located in Nashua, New Hampshire, the 180,000-square-foot plant is set to produce up to two billion aluminium beverage cans annually. The Nashua facility, formerly used by US industrial equipment manufacturer Ingersoll-Rand, has been repurposed and expanded to accommodate the rising demand for aluminium beverage cans. The facility will manufacture a variety of can sizes, including the popular 12oz (355ml) and 16oz (473ml) options, tailored to the needs of craft brewers and smaller beverage producers, particularly in the sparkling water, juice, and functional beverage sectors. Crown Holdings, a leading US-based can manufacturer, reported that nearly three-quarters of new beverage launches in North America now choose aluminium cans. This shift is primarily driven by consumers’ preference for the portability and recyclability of aluminium.

Announced projects for 2024 –

Aluminium canning plant in Alat – Hell Energy

Hell Energy Drink, a renowned company, is poised to transform Azerbaijan’s industrial landscape by establishing a cutting-edge facility dedicated to producing and filling aluminium beverage cans. Situated in the Alat Free Economic Zone, the upcoming plant, driven by advanced European technologies, marks the country’s entry into sustainable packaging solutions. This development, a result of a Joint Participation Agreement between Hell Energy and the Azerbaijan Investment Company, promises economic growth and a significant shift towards more sustainable beverage packaging. The establishment of this aluminium canning line holds great importance for Azerbaijan, not just in economic terms but also in its contribution to global sustainability efforts. By entering the aluminium beverage can production market, Azerbaijan aligns itself with the international movement toward environmentally responsible manufacturing, positioning itself as a leader in promoting economic development and ecological stewardship.

CBW to establish a new can-line

Craft Beverage Warehouse (CBW) in Milwaukee is set to embark on an ambitious growth trajectory, aiming to double its revenue by embracing innovation and adding a second multimillion-dollar digital print-to-aluminium can line at the Century City Business Park. Co-founder and President Kyle Stephens explained that the decision to invest in a second digital canning line was driven by the increasing demand for the company’s products. This advanced German-made printing technology allows CBW to print labels directly onto aluminium cans, offering enhanced flexibility and customisation for their clients. The expansion is a natural progression following the company’s successful introduction of digital can printing in the spring of 2022. The first digital can printing machine was installed at CBW’s Milwaukee facility in June. The technology serves a wide range of customers, including craft breweries, wineries, soda makers, and producers of THC- and CBD-infused beverages, enabling them to deliver high-quality, customisable packaging for diverse markets.

World Top Brewery marks its entry into the aluminium canned beer market

Wold Top Brewery, a beverage company based in East Yorkshire, has made a noteworthy leap into the canned beer market with a £100,000 investment in a new canning line. Their debut product, Wild Swim, is a 4 per cent ABV lager brewed by Henry Culpepper. Packaged in aluminium, Wild Swim is a clean, refreshing lager with a minimalist appeal, marking an exciting new chapter for the brewery. This investment was supported by the Farming Sustainability Fund, which aims to strengthen rural and farm-based businesses. The striking can designs were created by Carrot Juice Creative, a Leeds-based brand consultancy, adding a visually appealing touch to the brewery’s first foray into aluminium packaging.

Aluminium two-piece can production facility in Vietnam

Shanghai Baosteel Packaging announced plans to build a cutting-edge aluminium two-piece can production facility in Vietnam’s Long An province in the Mekong Delta region. With an investment of approximately RMB 525 million, the facility is designed to achieve an impressive annual production capacity of 800 million cans, reinforcing Baosteel Packaging’s strategy of “internal and external linkage.” This initiative aims to optimise production layouts, strengthen customer support, and expand service capabilities to serve the Southeast Asian market better. To drive this project, Baosteel Packaging will establish a new entity, Vietnam Hue Baosteel Can Longan Branch, under its wholly-owned subsidiary Vietnam Baosteel (Hue). The new production base will address growing market demand in Vietnam and aligns with Baosteel Packaging’s strategic goals of expanding its international footprint, enhancing customer service, and boosting its competitiveness for sustainable long-term growth.

MZB-USA partners with Ultramar Caffè

Massimo Zanetti Beverage USA (MZB-USA), headquartered in Virginia, announced a strategic partnership with Ultramar Caffè – La Natura Lifestyle to establish a new packaging line aimed at meeting the rising demand for aluminium espresso capsules in the US market. The new line will be installed at MZB-USA’s manufacturing facility in Suffolk, Virginia, with the installation expected to be completed by the second half of 2024. This new line will enable MZB-USA to produce up to 100 million aluminium capsules annually, supporting its well-known brands, including Chock full o’Nuts, Hills Bros, Kauai Coffee, and Segafredo Zanetti. Initially, the capsules will target the e-commerce and food service sectors. MZB-USA highlighted that this partnership will also allow the company to serve as a third-party supplier for major brands looking to expand within the aluminium capsule segment.

Ball Corporation’s new manufacturing facilities in Llinars del Vallés

Ball Corporation, a global leader in sustainable aluminium packaging for beverages, personal care, and home products, had expanded its portfolio in extruded aluminium packaging by acquiring Alucan, a leading European producer of extruded aluminium aerosol and bottle technology, on October 31st. This acquisition included the addition of new manufacturing facilities in Llinars del Vallés (Barcelona), Spain, and Lummen, Belgium, further bolstering Ball’s commitment to delivering scalable, sustainable packaging solutions to its customers. The new facilities will help Ball meet the rising demand for sustainable packaging across Europe, with both plants equipped with advanced technologies designed to minimise environmental impact. This acquisition also enhances Ball’s capabilities, introducing large-diameter aerosol cans and impact-extruded bottle options while strengthening its support for reusable bottle customers. By diversifying its customer base, Ball will create cross-selling opportunities with food and beverage manufacturers and expand its offerings to include personal care and home products. Additionally, Ball plans to drive innovation by lightweight Alucan cans and increasing their recycled content, further aligning with its sustainability goals and carbon footprint reduction efforts.

Conclusion

In 2024, the aluminium packaging industry is charting a bold course towards innovation and sustainability with impactful projects across the globe. From Gunna’s bottling plant in the UK to Can-One USA’s expanded facility in New Hampshire and future ventures like Hell Energy’s Azerbaijan canning plant, the sector is scaling up to meet eco-conscious consumer demands. These initiatives spotlight aluminium’s rising prominence, driven by its unparalleled sustainability, endless recyclability, and versatile applications. By prioritising operational excellence, eco-friendly practices, and tailored solutions, the industry is reshaping the future of packaging. As it expands to meet the demands of a greener market, aluminium is solidifying its role as a cornerstone of sustainable packaging innovation.