The aluminium industry is undergoing a revolution powered by AI and automation. From extrusion to smelting and rolling, cutting-edge technologies drive efficiency, sustainability and cost-effectiveness.

This blog explores three case studies highlighting how industry leaders leverage digital transformation to optimise operations and reduce environmental impact.

Granco Clark: Adaptive Technology in Aluminium Extrusion

Granco Clark is at the forefront of aluminium extrusion innovation. In 2024, the company introduced adaptive technology, a software package that enables extrusion equipment to self-tune in real-time. Unlike conventional systems that rely on preset configurations, this smart software continuously monitors process metrics and makes automatic adjustments to maximise efficiency and extend equipment lifespan.

Another breakthrough is Granco Clark’s fully electric ePuller system. Unlike traditional hydraulic pullers, this servo-driven digital system enhances speed, reliability and diagnostics. Early adopters have reported higher throughput and significantly reduced downtime, marking a substantial leap in operational efficiency.

(Source: Granco Clark)

Quaker Houghton: Smart Fluid Intelligence

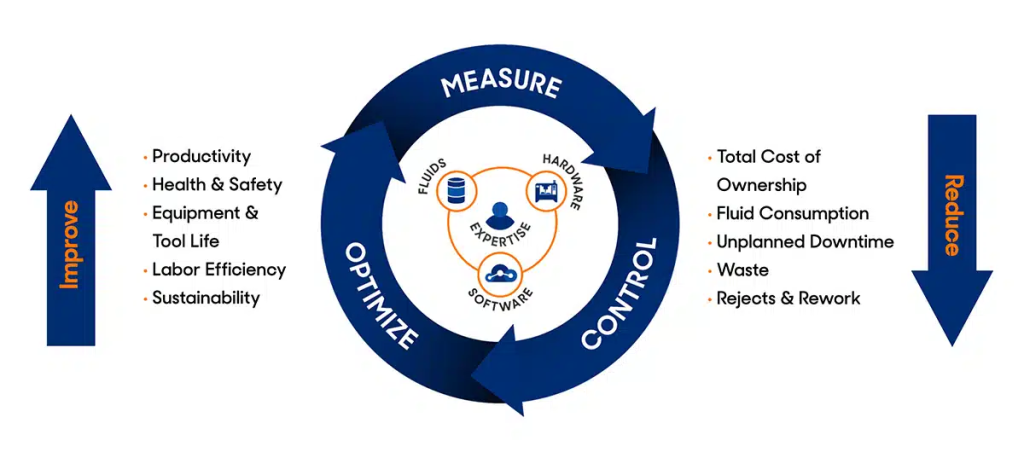

Quaker Houghton, a global leader in process fluids, has pioneered the QH FLUID INTELLIGENCE platform, an automated system that provides real-time monitoring and control of fluid performance. Managing lubricants and coatings manually can be time-consuming and error-prone. This platform utilises sensor technology to track key parameters such as pH, temperature and conductivity, ensuring fluids remain in optimal condition.

One remarkable application is in the conversion coatings process, where aluminium must be cleaned before coating. Previously, manual acid-split tests took up to 10 hours, delaying real-time adjustments. With QH FLUIDCONTROL WMS 100 hardware and QH FLUIDTREND software, real-time measurements allow automatic adjustments, ensuring consistent quality and reduced process time. This automation enhances both productivity and surface quality, making production more reliable and efficient.

(Source: Quaker Houghton)

Hamilton Research: AI-Powered Pot Control & Anode Baking

Hamilton Research has developed two flagship systems – REDCON and FIRECON, that are redefining process optimisation in aluminium smelting. REDCON is a pot control system that leverages AI-driven predictive analytics to optimise alumina feed, manage real-time resistance and minimise anode effects. The result? Improved current efficiency and reduced power consumption.

FIRECON, designed for anode baking furnaces, uses AI to maintain precise temperature profiles, optimise fire-change routines and minimise emissions. Its predictive maintenance capabilities analyse historical and real-time data, allowing proactive interventions that prevent breakdowns. The integration of machine learning algorithms enables smarter decision-making, contributing to energy efficiency and a lower carbon footprint in aluminium production.

(Source: Hamilton Research)

Conclusion

The aluminium industry’s digital transformation is no longer a distant vision, it is happening now. Companies like Granco Clark, Quaker Houghton and Hamilton Research are paving the way with AI-powered solutions that boost productivity, reduce environmental impact and enhance cost efficiency. As more manufacturers adopt smart technologies, the industry moves closer to a fully automated, data-driven future.