As the global packaging industry transforms under the weight of environmental responsibility, changing consumer preferences, and regulatory pressures, one material is increasingly capturing the spotlight: Aluminium.

Lightweight, infinitely recyclable, and incredibly versatile, aluminium packaging isn’t just a trend — it’s becoming a necessity. From beverage cans to coffee capsules and pharma blister packs, aluminium is leading the charge in sustainable packaging innovation, and it’s time for both consumers and brands to pay closer attention.

The sustainability imperative: Why aluminium wins

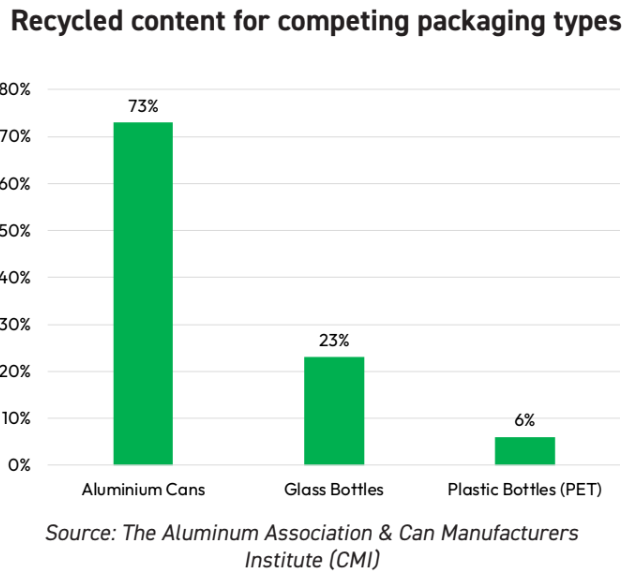

Let’s face it — the world is in a packaging crisis . Consumers are demanding greener alternatives, and governments are laying down stricter environmental regulations. In this landscape, aluminium’s infinite recyclability and high scrap value position it ahead of plastic and even glass.

Did you know that nearly 71% of all aluminium cans globally are recycled? That makes them the world’s most recycled beverage container. In markets like Brazil and Japan, recycling rates exceed 90%. Compare that to plastic bottles, which are often downcycled — or worse, incinerated or landfilled.

Aluminium’s closed-loop recycling system means that a can you recycle today could be back on a store shelf in as little as 60 days. That’s the circular economy in action.

Convenience meets consciousness: Aluminium aligns with consumer demand

Today’s consumers are more conscious than ever — of what they consume and how it affects the planet. Aluminium’s clean design, lightweight, and ability to preserve product freshness play directly into that mindset. Brands like Nespresso, Coca-Cola, Dove, and Billy Water have embraced aluminium not just to reduce plastic waste, but to connect with eco-aware buyers.

Globally, aluminium packaging usage in the food and beverage sector alone was recorded at several million tonnes in 2023, and it’s expected to reach much higher levels than we think is possible today. That’s not just growth — that’s a shift in mindset.

From cans to capsules: Where aluminium is gaining ground

The beauty of aluminium lies in its flexibility. Whether you’re looking at sleek cosmetic tubes, robust aerosol containers, pharma blister packs, or coffee capsules, aluminium is adapting — and thriving — in each category.

- Beverage cans: Forecast to grow from 416 billion units in 2020 to 627 billion units by 2030.

- Foil packaging: Dominates in frozen meals, bakery items, and ready-to-eat foods.

- Pharmaceutical packaging: Aluminium’s tamper-proof and light-barrier properties make it a critical player in health and wellness.

- Coffee capsules: With aluminium pods offering both recyclability and superior aroma preservation, it’s no wonder companies like Nespresso are doubling down.

This isn’t just material science — it’s strategic design meeting sustainability.

Innovations that matter: RE-LID, thin-gauge foils, and plant-based coatings

As brands compete in crowded aisles and digital feeds, design and differentiation matter more than ever. Aluminium doesn’t disappoint.

Take RE-LID, the re-closable aluminium beverage cans developed by Aluflexpack and REL. It addresses two consumer pain points — waste and convenience — while staying fully recyclable. Or consider Coca-Cola Japan’s use of Toyo Seikan’s lightest aluminium can (6.1g), which reduces GHG emissions by 8% per unit.

New technologies are also enabling thinner foils, plant-based internal coatings, and more customisable labelling. In short, aluminium isn’t static — it’s evolving.

What brands need to know: It’s more than just a material switch

Switching to aluminium is more than swapping out packaging — it’s a brand repositioning. It tells your customers you care about:

- Sustainability and circularity

- Product quality and preservation

- A premium, modern consumer experience

Brands that embrace aluminium can signal leadership, not just compliance. And with government incentives and consumer loyalty increasingly tied to ESG performance, it’s a savvy strategic move.

The road ahead: Challenges and call to action

Yes, aluminium production is energy-intensive — and yes, there’s work to be done to decarbonise the supply chain. However, with the rise of green aluminium (produced using renewable energy) and improvements in smelter efficiency, these issues are being actively tackled.

The aluminium packaging sector is committed to halving its carbon intensity by 2030 and reaching net zero by 2050. But we can’t do it alone. Brands, consumers, recyclers, and policymakers need to collaborate.

Our take:

We believe aluminium packaging is not just a responsible choice — it’s the smart choice for the future. The momentum is real, the technology is ready, and the consumer is waiting. For those who are willing to lead, aluminium offers the perfect intersection of innovation, impact, and integrity.

Whether you’re a brand looking to enhance your ESG credentials or a consumer wanting to vote with your wallet — now is the time to choose aluminium.

Let’s package the future — sustainably.

Dive deep into the evolving world of aluminium packaging — from cans and foils to pharma blister packs, cosmetic tubes, and more. Discover global trends, market insights, and product-wise usage forecasts that matter to your business. Subscribe now to “ALuminium in Packaging: Consumer Trends and Market Dynamics” — your definitive guide to innovation, sustainability, and growth in the aluminium packaging sector.