Aluminium is a popular choice for manufacturers for a variety of reasons. When appropriately allowed and tempered, it’s stronger than some steels. Tensile strength as high as 80,000-90,000 psi is possible. Yet, the end product is lighter and often stiffer than some steel parts.

It’s also corrosion-resistant and not impacted by extreme cold temperatures, unlike plastic and some steel parts.

Other benefits of aluminium:

- Conducts electricity more economically than copper

- Dissipates heat more efficiently than other metals

- Sustainable and recyclable without degradation

- Can be formed into complex shapes and geometries

Aluminium extrusion has become increasingly popular, especially in the automotive sector. It’s particularly relevant for EVs and batteries. For example, Tesla’s Model S and Model X use aluminium for chassis and body structures to reduce weight and increase range. Aluminium now makes up 40 per cent of the Audi e-tron’s structural components.

Aerospace, construction, and consumer electronics also rely heavily on aluminium extrusion for its lightweight properties, durability, and design flexibility.

The aluminium extrusion process

The aluminium extrusion process flows through a series of steps to go from a soft (malleable) state to a finished product. Let’s tackle it step by step and look at some of the recent innovations making the extrusion process more efficient.

- Billet preparation

With extrusion, you’re not melting the alloy; you are heating and forming it.

Billets are preheated in induction or gas-fired furnaces to a temperature of 400-500°C (750-900°F). The heating process is carefully controlled to ensure there is a uniform temperature distribution. Variations can cause uneven material flow during extrusion and lead to defects. Overheating can produce oxidation.

Depending on the size of the billet and the alloy composition, the preheating process can take several hours to reach the desired temperature.

Recent innovations

Advanced induction heating systems are gaining in popularity, with the ability to reduce energy consumption significantly compared to gas-powered furnaces. They also heat billets more quickly.

- Die preparation

Different dies can be used to create the patterns needed. In some cases, dies can create several different component shapes at the same time. The process uses computer modelling to predict material flow and optimise the geometry.

Extrusion dies are typically made from high-strength tool steel, such as H13, and preheated to prevent thermal shock when the hot billets come into contact with the surface.

Recent innovations

Several recent innovations have emerged in this stage, including the use of AI tools to optimise die design and advanced surface coatings, such as diamond-like carbon (DLC), to extend die life.

- Extrusion press

The extrusion press is a hydraulic machine that applies force to push the heated billet through the die, with some modern presses capable of exerting some 15,000 tons of force. Ram speeds can vary between 5 and 50 mm/s depending on the alloy.

The heated billet is loaded into the container, and a hydraulic ram applies the necessary pressure. Control systems monitor pressure, temperature, and speed throughout the extrusion cycle. Depending on the alloy and component, servo controls can allow for variable speed and pressure to optimise material flow and quality.

Recent innovations

In an effort to reduce energy use and costs, some systems now include energy recovery capabilities, resulting in reductions of up to 30 per cent.

- Profile emergence

As the aluminium flows through the die, it emerges with the shape of the die opening. It is supported by a run-out table to prevent sagging or distortion.

Recent innovations

Some extrusion processes use a puller system that automatically adjusts to different profiles. For example, laser-based dimensional monitoring can detect even minute variations to ensure quality.

- Quenching

Immediately after the formed component emerges, the quenching process begins. This is a rapid cooling process using water spray or high-velocity air cooling to lock in the structural integrity of the component.

The cooling rate is critical at this phase. If it’s too fast, it can cause defects or create internal stress. Too slow, and you can impact the final mechanical properties as well. The process is quick, reducing temperatures to approximately 60-80°C (140-175°F) in under a minute.

Recent innovations

Mist cooling systems and zone-controlled quenching with independent temperature monitoring can adapt to multiple profiles and adjust cooling intensity based on profiles and real-time temperature monitoring.

- Stretching

After quenching and cooling, aluminium profiles undergo a stretching process to relieve any internal stress and enhance component accuracy. Both ends of the profile are gripped, and controlled tension is applied. Depending on the alloy and geometry, stretching typically results in an elongation of 1-3 per cent.

Recent innovations

Modern equipment includes servo-controlled stretchers that apply force and monitor the elongation process to verify geometric accuracy during the stretching process.

- Cutting and aging

Profiles are next cut to length using saws. This can be done on the fly as profiles move or with a stationary cut-off saw.

After cutting, the aging process begins. Depending on the alloy, the profile is then reheated for several hours to a temperature between 160 °C and 200°C (320°F and 400°F). The artificial aging process is necessary to improve the hardness and yield stage.

Recent innovations

Research shows that a two-step aging process, coupled with deformation, can significantly reduce aging time by nearly 90 per cent and improve tensile strength.

- Surface treatment

The final step in the aluminium extraction process is a surface treatment for appearance, corrosion resistance, and durability. One of the most common treatments is anodising, which is an electrochemical process that produces a protective layer on aluminium surfaces. Profiles are immersed in an acid bath and subjected to electrical current, which causes the surface to form an oxide layer that can be dyed and sealed.

Another option is powder coating. Electrostatically charged powder particles are applied to the surface and then cured in an oven to create a durable and uniform finish. Mechanical finishing can also include brushing or polishing to achieve the desired surface textures.

However, for many applications, aluminium does not require any finishing. Over time, exposure to air creates a thin, transparent oxide film that naturally protects the surface.

Recent innovations

Recent innovations include plasma electrolytic oxidation and the increasing use of lasers for surface modifications, especially for surface texturing when components are joined.

Extrusion process methods

About 90 per cent of production uses direct extrusion, where the billet moves against a stationary die. However, the higher friction requires more power. So, some manufacturers will use an indirect extrusion process. Here, the billet is stationary, and the die moves towards it. The indirect method uses up to 40 per cent less power and is most effective for hard alloys.

Other methods include hydrostatic extrusion, where fluid pressure is used instead of force. This makes lower temperatures possible and is excellent for complex shapes. Conversely, impact extrusion uses a high-speed punch to drive alloys through dies. This is more common for cans and containers using a cold extrusion process.

Managing alloys and traceability

One particular challenge in the aluminium extrusion process is quality. With casting, you melt different alloys to make parts. You can tightly control properties, mixing and testing combinations to find the right blend. In extrusion, you are heating and forming with no real control of the alloy mix. As a result, traceability becomes essential.

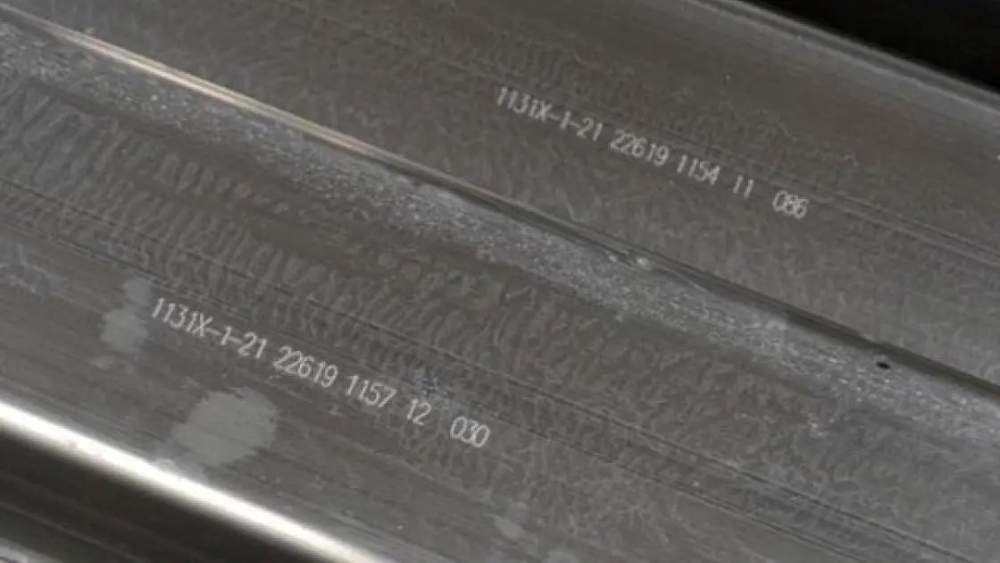

Between pressing and quenching, lasers can mark aluminium components to validate alloy types in extruded profiles and ensure traceability. By providing a permanent mark that can withstand harsh environments, unique identification numbers are applied to facilitate easier tracing in the event of recalls.

Laser marking provides reliable inline traceability without impacting throughput. For automotive manufacturers, this allows organisations to meet requirements for certifications like ISO 9001 and IATF 16949 and OEM requirements for traceability.

Modern laser marking technology can serialise extrusions and identify scrap on the fly when it exits the press. Autofocus tech can create high-contrast, human-readable barcodes and characters on any profile shape to ensure traceability.

Meeting increased demand

As demand accelerates for stronger, lighter, and more sustainable components, aluminium extrusion continues to grow in importance.

With ongoing advances in AI-driven design, adaptive machinery, real-time quality assurance, and laser marking for traceability, the manufacturing process is becoming more efficient than ever.