Aluminium is a material used in almost every industry and is on the list of critical raw materials in many developed countries.

Aluminium as a critical raw material

Aluminium is a key material for strategic industries, particularly defence, aviation and renewable energy. Primary aluminium production is an energy-intensive process. Almost half of global primary aluminium production is produced by China. However, recycled aluminium can replace primary aluminium in many applications.

Thanks to the recyclability of aluminium, the import dependency of economies decreases with the increase in local production. The pandemic has highlighted the importance of local production of critical materials like aluminium. The disruptions in supply chains during the pandemic have caused significant difficulties for foreign-dependent economies.

Aluminium as a sustainable material

We are experiencing a state of unsustainability on a global scale and in this unsustainable situation, the measures taken are not very useful, at least for now.

The great technological advances of the past centuries, along with the industrial revolution, have made our lives easier and extended human lifespans. Still, they have left us with three formidable problems:

- Constraints resulting from the irresponsible use of raw materials and energy resources

- Environmental destruction

- Related social problems

Humanity is searching for ways to build a sustainable future, that is, to transition from linear dystopia to circular utopia.

In the linear economic approach, recycling creates value from waste; in the circular economic approach, it makes a “new raw material source” with developing technological, economic, cultural and political capabilities. Recent trade disputes show us the importance of this issue.

In this context, recycling can be defined as a new resource alongside traditional raw material sources such as water, air, oil, natural gas, coal and minerals. Aluminium is the metallic material with the highest recyclability rate compared to other metallic materials.

Dilemma

We need more metallic materials to build a low-carbon future.

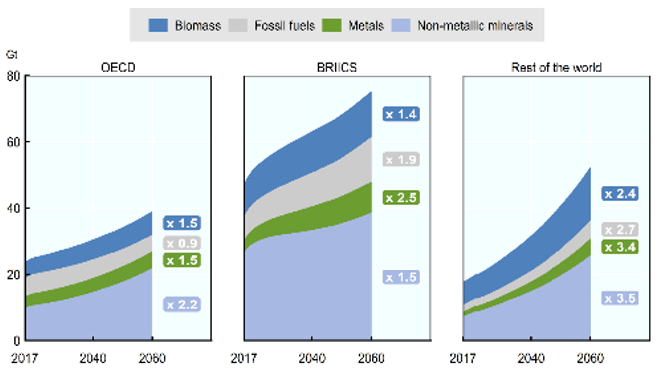

According to the World Bank’s “Global Material Resources Outlook to 2060” report, limiting global warming to at or below 1.5°C–2°C, to realise a low-carbon future, requires a large-scale transition to clean energy. Manufacturing solar panels, wind turbines and batteries will shape the supply and demand for critical minerals for the foreseeable future.

The clean energy transition and global development imperative will be mineral-intensive, with the World Bank estimating that demand for key critical minerals could skyrocket by nearly 500% by 2050 under a 2-degree scenario.

Figure: Growth in materials use is projected for all regions (Source: Global Material Resources Outlook to 2060, Wordbank)

Aluminium as an engineering material:

Henry Gordon Stott, the famous American engineer who designed and implemented New York City’s transportation infrastructure, defines engineering as follows:

“The art of organising and directing man and controlling the forces and materials of nature for the benefit of the human race.”

Because at that time, “technology” was perceived as humanity’s effort to control nature. However, today, “technology” can be defined as humanity’s effort to progress alongside nature.

When we consider the concept of sustainability as a holistic “system,” aluminium offers engineers two significant opportunities:

- Its ability to be recycled directly makes metallurgical processes sustainable

- Aluminium and its alloys indirectly serve sustainability goals during their use, with their properties such as lightness, high mechanical strength and high corrosion resistance

Recycling

The International Aluminum Institute recommends three approaches to achieving the 2050 carbon neutrality target:

Electricity decarbonisation

- The transformation of energy production infrastructure from fossil fuels to renewable resources

- Carbon capture, utilisation and storage

- To increase energy efficiency

Direct emission potential

- carbon capture, utilisation and storage

- inert anode

- refinery and casthouse electrification

Recycling and resource efficiency potential

- Near 100% post-consumer scrap collection and alloy sorting

- Elimination of pre-consumer scrap

- Elimination of all metal losses during casting and recycling

Considering the technological level we have reached today, the transformation of the energy production infrastructure from fossil fuels to renewable resources, the problems of storing electrical energy produced from renewable resources and technologies such as CCUS and inert anode, which have not yet proven themselves on an industrial scale. In other words, we are still in the development process; the most important path we have left in the short and medium term is “recycling”.

Conclusion

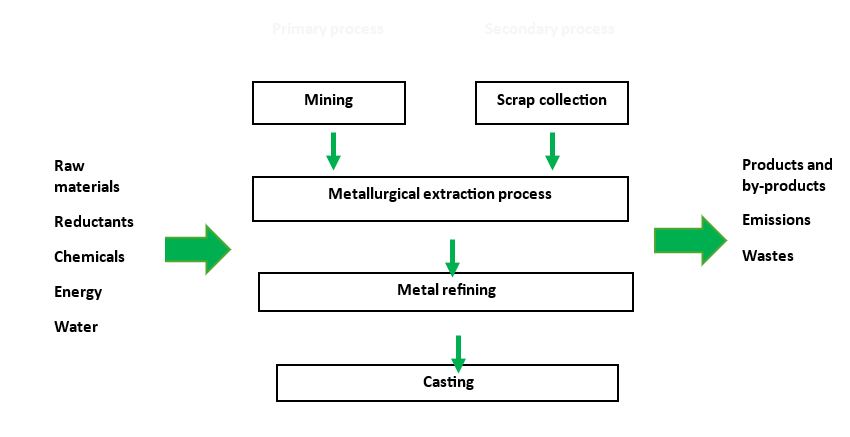

From a metallurgical perspective, primary and secondary metal production methods operate in parallel with each other in terms of main principles.

Figure: Primary and secondary metallurgical processes

Taking into account the parallelism in primary and secondary metallurgical processes, the following relationships can be established:

- low-grade ore processing technologies ↔ recycling technologies

- poly-mineral ore processing technologies ↔ recycling technologies

- recycling ↔ efficient use of resources

- In the context of sustainability, it is possible to define the following relationships for the aluminium recycling process:

- recycling ↔ energy efficiency

- recycling ↔ carbon emissions control

- Based on energy efficiency, the following relationships emerge:

- energy efficiency ↔ metal efficiency

- energy efficiency ↔ productivity

- energy efficiency ↔ low carbon emission

If we take into account that the by-products formed in both primary and secondary production processes can also be evaluated through recycling technologies:

- by-products processing ↔ waste control

- And economically:

- local resource utilisation ↔ economical safety

- local resource utilisation ↔ new employment areas

Let this be the final sentence: Recycling is the never-ending story.

Erman bey kutlarım çalışma gayet güzel olmuş emeğine sağlık