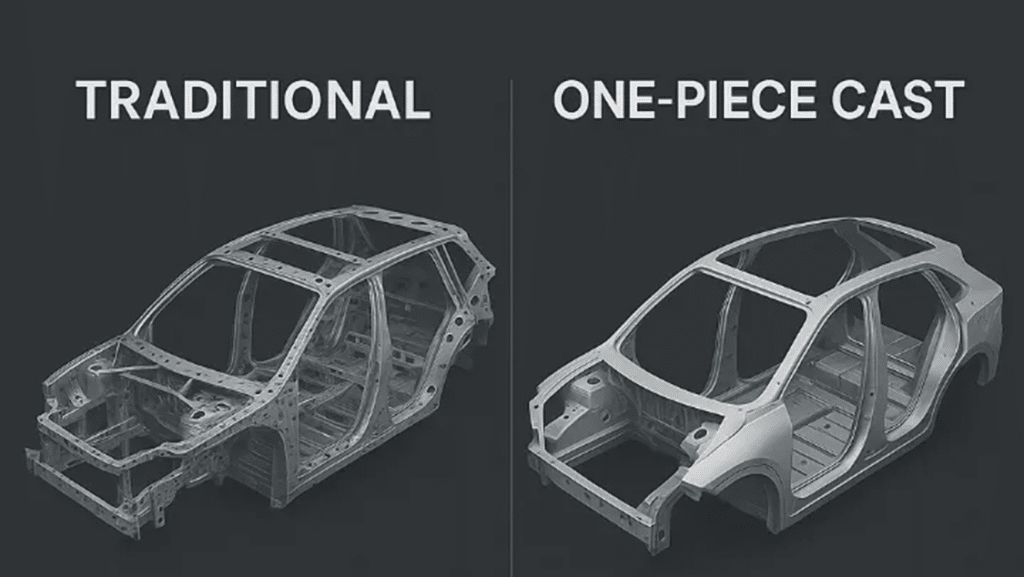

Some innovations don’t just improve a product, they rewrite the engineering playbook. That is exactly what Chinese automotive supplier Hubei Hantek Equipment Manufacturing Co., Ltd. has done by introducing the world’s first one‑piece, low‑pressure‑cast, all‑aluminium large vehicle frame, now installed in BYD’s premium SUV.

A structural breakthrough in vehicle engineering

At the 2025 Yangtze River Industry and Technology Innovation Conference in Hubei on December 2, 2025, Hantek unveiled an aluminium frame that pushes material and casting limits. Covering 4.2 square meters with wall thicknesses from 4 mm to 50 mm, this frame achieves an unprecedented 12:1 thickness ratio, something no global automotive aluminium casting project had accomplished before.

Image credit: Manufacturing Today

Traditional aluminium frames are assembled from dozens of welded or riveted parts, creating weak points and raising manufacturing costs. Hantek’s single‑piece design eliminates these joints. The result: higher structural rigidity, fewer fatigue failures and improved crash performance, all while simplifying production.

Solving tough casting challenges

This feat was not simple. Hantek spent years refining low‑pressure casting techniques for oversized thin‑walled components, fine‑tuning molten metal flow, controlling fill rates and managing solidification gradients across extreme thickness variations. These process innovations, supported by proprietary aluminium alloys and optimised heat‑treatment cycles, enable the frame to maintain high strength, toughness and fatigue resistance, critical for demanding automotive use.

Industry officials highlighted this achievement as a major milestone in China’s capabilities for large, complex aluminium structural components, with the potential to reshape how future electric SUVs and pickups are engineered.

A showcase in a luxury electric SUV

The one‑piece frame is installed in the BYD Yangwang U8L, a luxury electric SUV launched in September 2025 and priced at around 1.28 million yuan (USD 181,200). Built on BYD’s advanced e4 platform, the U8L boasts a powerful hybrid and multi‑motor setup with a Blade battery, 880 kW output, multiple drive modes and executive‑class features.

What this means for the aluminium value chain

This innovation goes beyond a single vehicle model. Hantek collaborates with other major OEMs such as Nio, FAW Hongqi and Dongfeng Lantu, meaning the impact of large one‑piece aluminium castings could spread widely across the electric vehicle market. As low‑pressure casting competition grows, manufacturers are increasingly applying these technologies to large body modules, subframes and EV battery tray areas where aluminium’s strength, weight savings and design flexibility deliver real value.

In an industry where lightweight structural performance and manufacturing efficiency are decisive factors, this breakthrough stands as a testament to the role of advanced aluminium engineering in next‑generation EV design.

Source: Hubei introduces world’s first one-piece large aluminium frame installed in BYD vehicles