Introduction

Aluminium, as a wonder metal used to make extrusions, has surely come of age and is widely accepted in home and industrial applications alike. However, there are always innovations being considered to further lower the operational costs during extrusion. Since there are very limited possibilities of further giving the final shape of the extruded section and reworking, any effort to reduce the losses in reworking/rejections would result in a competitive finished product, particularly for the small extruders. Hence, an effort has been made in this article to uncover possible solutions.

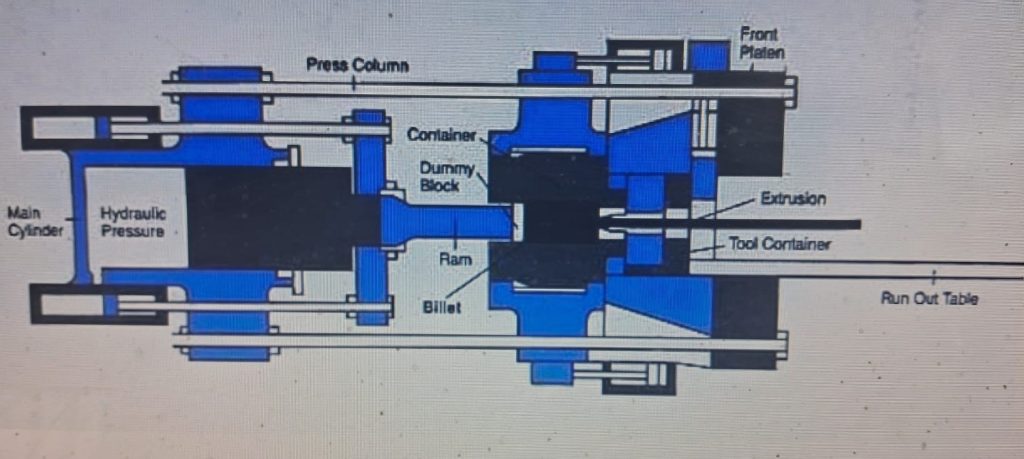

Diagram of a typical horizontal hydraulic extrusion press

Basic mechanics of the extrusion process

Depending upon the extrusion ratio, a round pre-heated billet is forced against a die section in a continuous process to produce the desired length of the section. Since every action has an equal and opposite reaction, forcing metal from a fixed, bigger diameter to a smaller cross-section would entail a backward flow of partially oxidised metal because of the intense heat generated by the extrusion process. This action becomes more pronounced during the initial stages till the metal starts to flow smoothly through the die. As a result of this, there exists a greater possibility of the extruded surface developing scars, which need to be cut or discarded as scrap for remelting, thus reducing the output/ input ratio. This obviously would lead to reduced margins and /or loss of profitability.

A Possible Solution?

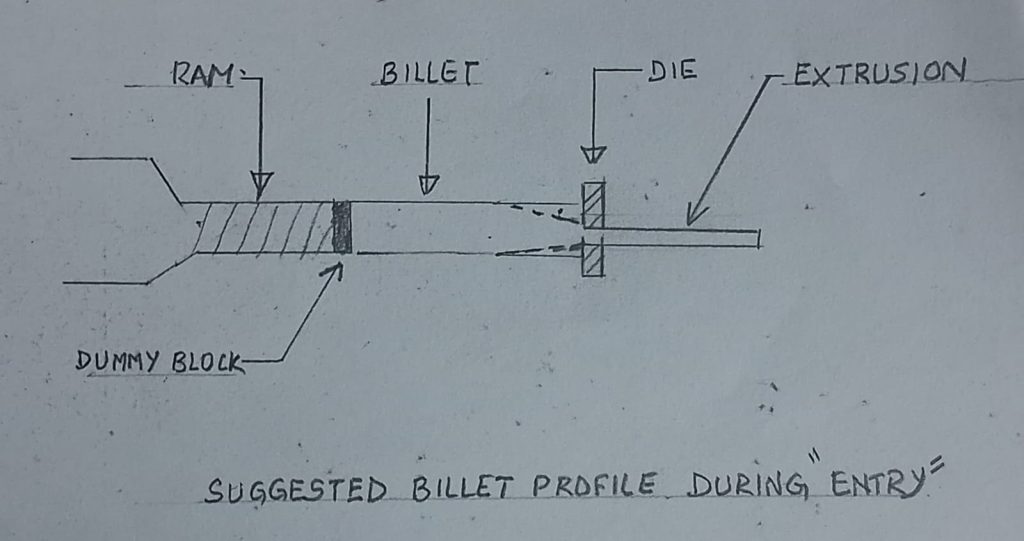

Taking a cue from the fluid flow fundamentals, if the shape of the entry head of the billet is cast in a tapered shape, it would lead to a relatively smoother flow of the billet into the die during the initial stage, with a much-reduced back flow of the metal and fluctuation in hydraulic pressure.

Pictorial representation of the suggested extrusion processing

Possible challenge envisaged

Reduction in output/input ratio and/or fill ratio, however, can be compensated by reduced rejections/end cut-offs. A trade-off will have to be established with experimentation.

Projected benefits of the solution

- Lower end cut-offs and rejections mean improved margins.

- Better surface finish, either as extruded or oxidised/painted, means better customer satisfaction.