Introduction

The basic question: Which is better for carrying current, copper or aluminium? For decades, the conventional wisdom has been that copper is better because it has higher electrical conductivity. Afterall, copper is “The Metal of Electrification.” This fundamental belief has been outdated for 80 years, since aluminium became available in industrial quantities after World War II.

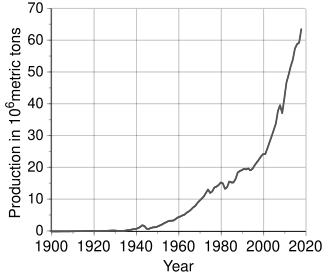

Figure: Global Production of Aluminium from 1900-2020

The truth is that aluminium has double, 200 per cent, the weight-conductivity of copper! Furthermore, today copper costs four times as much, so one dollar’s worth of aluminium can provide the same current-carrying capacity as eight dollars’ worth of copper.

Artificial intelligence and copper panic

A January 2026 S&P Global report predicts that the demand for copper in the “New Age of AI” will exacerbate the already existing copper shortages. There will not be enough copper to build data centres, the brains of AI and the increased electric infrastructure needed to supply them.

Figure: World Economic Forum

In a recent interview at the World Economic Forum in Davos, Switzerland, Elon Musk said that many AI chips will soon be produced and a substantial portion of them will never be turned on because there won’t be enough electricity. Electricity is like oxygen in our brains. Oxygen deprivation has well-known consequences. Similarly, not enough electricity could short-circuit data centres’ ability to function.

Consequently, the need for more electricity is now showing up on everyone’s radar. This means that more generating plants and power lines are needed. To address concerns about the ability to get new lines built, ideas for siting new generating facilities collocated with data centres are even being considered.

This apparent need for more electricity and power lines has people thinking that more copper will also be needed. Afterall, copper is “The Metal of Electrification”.

Let’s look at examples of “copper panic” among some mega-cap technology companies and how they are reacting to shortages and record-high copper prices.

Example 1: Tesla Motors

Figure: Tesla Motors’ logo

Tesla Motors announced that it is changing the low-voltage power system in its EVs from 12 volts to 48 volts to reduce the amount of copper. (The Tesla Model S, for example, has a mile of copper just to connect the battery to the electronics.)

Increasing the voltage to reduce copper is a good strategy. However, a better one would be to also replace the reduced copper with aluminium. The aluminium would carry the same amount of current and provide additional benefits of reduced weight and cost.

Tesla engineers already know a lot about aluminium, its “strength-to-weight” ratio and how to design EV structures to take advantage of that ratio. Now they need to adopt a similar approach for electric design using a new metric: “conductivity-to-weight” ratio.

Example 2: Tesla Optimus Robots

Figure: Tesla Optimus Robots

Of late, Tesla is reported to be transitioning from traditional EVs to autonomous vehicles and humanoid robotics. Elon Musk has stated his belief that the Optimus Robot is the company’s future. Like EVs, these robots are electrical devices that can also benefit from using aluminium to carry current instead of copper.

Example 3: Nvidia

Figure: Nvidia

NVIDIA, the AI data centre chip producer, recently indicated that millions of pounds of copper busbar will be needed to build a data centre. Copper supply shortages and escalating prices can be avoided by using aluminium busbar. Extruded aluminium busbar can provide the same current-carrying capability as copper with reduced weight and cost. It is a proven product that has been quietly replacing copper busbar for decades.

Example 4: Amazon

Figure: Amazon Web Services

Amazon’s Web Services, the Data Center Division of Amazon, has announced a partnership with Rio Tinto mining to develop a new domestic supply of copper.

Example 5: Rio Tinto

Figure: Rio Tinto

Rio Tinto is also a big producer of aluminium. Since copper and aluminium are fungible for carrying current, Amazon Web Services could switch to aluminium, avoid copper supply issues and realise weight and cost savings.

Beyond Tesla, Nvidia and Amazon

Figure: High Tariffs

Tariffs and the rearrangement of international manufacturing sites are causing global businesses to build new plants in the United States for the first time in decades. Industrial plant specifications have historically called for copper conductors and were never updated to permit aluminium, as electrical utilities did. Now, projected copper shortages and increasing prices may motivate companies to update their specs so that they can use copper or aluminium.

The Grid

Figure: The Grid

It has been suggested that there won’t be enough copper to modernise and expand the ageing electric grid. What is being overlooked is that electric utilities have already completely switched from copper to aluminium after World War II. Today, the entire transmission and distribution grid of the United States is comprised of aluminium.

Conclusion

Copper panic, the fear that there will not be enough copper to build data centres and electrical infrastructure to supply them, is based on outdated information. More than enough aluminium is available to do the job. The answer to the basic question at the beginning of this article, which is better for carrying current: copper or aluminium, is obvious; aluminium is much better than copper for carrying current.

“Change the way you look at things, and the things you look at change.”

The following Appendix summarises what one needs to know:

Material Properties

- Aluminium has twice the weight conductivity of copper.

- Aluminium weighs just one-third as much as copper.

- One pound of aluminium provides the same current-carrying capacity as two pounds of copper.

Supply

- Aluminium production has increased tremendously since World War II. In just ten years, 1945-1955, aluminium production surpassed that of copper and continues to increase.

- Today, roughly three times more aluminium than copper is being produced.

- Aluminium is the third most abundant element in the Earth’s crust after oxygen and silicon.

- Copper prices are skyrocketing and are predicted to go higher because of constrained supply.

- The price ratio of copper to aluminium is now roughly four to one.

Bottom Line

- Aluminium now has an eight-to-one cost advantage over copper: $1 worth of aluminium provides the same electrical function as $8 copper.

- Aluminium prices are more stable than copper prices

- Aluminium is less prone to theft