Aluminium is a material of choice across industries, thanks to its unique strength, flexibility, and lightweight properties. At the core of utilising this remarkable material lies the aluminium extrusion process.

This guide focuses on the world of aluminium extrusion, shedding light on its applications and the diverse range of aluminium profiles available at Tuli Shop. Whether you’re a seasoned professional, a DIY enthusiast, or exploring the potential of aluminium for the first time, this guide is just the right resource for you.

What Makes Aluminium Ideal for Extrusion?

Aluminum is the preferred material for extruded profiles due to its unmatched combination of properties:

- Lightweight and Strong: Ideal for industries needing materials with high strength-to-weight ratios.

- Corrosion Resistant: Ensures durability in challenging environments.

- Malleable and Ductile: Perfect for creating intricate shapes through extrusion.

- Thermally Conductive: Essential for applications requiring effective heat dissipation.

- Sustainable: Fully recyclable, making it a top choice for environmentally conscious industries.

From construction and automotive to industrial machinery, aluminium’s versatility, adaptability, and sustainability make it indispensable.

The Aluminium Extrusion Process

Aluminium extrusion transforms raw aluminium alloys into profiles with specific cross-sectional shapes. Here’s an overview of the key steps:

- Billet Preparation: Cylindrical logs of aluminium alloy are heated to improve malleability.

- Container Heating: Preheating reduces the extrusion force and ensures a smoother process.

- Die Heating: The custom die, made from tool steel, is heated to withstand extrusion pressures.

- Billet Loading: The heated billet is placed in the press container.

- Extrusion: Pressure forces the aluminium through the die, forming the desired profile.

- Cooling: The extruded profile is rapidly cooled to set shape and maintain structural integrity.

- Stretching and Straightening: Profiles are stretched and aligned to reduce internal stresses and meet tolerances.

- Cutting to Length: Profiles are precision-cut to specified lengths.

- Surface Treatment (Optional): Profiles can be anodised, painted, or powder-coated for enhanced appearance and durability.

- Quality Control: Rigorous checks ensure dimensional accuracy, surface finish, and compliance with design specifications.

Diverse Aluminum Profiles at Tuli Shop

Aluminum extrusion offers unparalleled versatility. At Tuli Shop, we embrace this potential by providing a broad range of profiles for various applications, including:

- T-Slotted Profiles: Ideal for modular structures, frames, and workstations.

Example: 30×30 U8 aluminum profile. - Round Profiles: Lightweight and sleek, perfect for projects prioritising aesthetics.

Example: Φ28 aluminium profile. - Multi-Channel Profiles: Designed for complex structures requiring multiple channels.

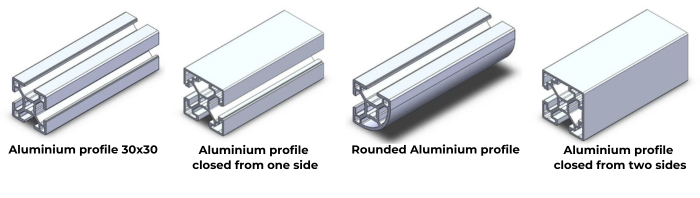

Example: 90×180 U10 aluminum profile. - Closed and Rounded Profiles: Excellent for applications emphasising a polished aesthetic appearance.

Applications across Industries

- Architecture and Construction

Extruded aluminium profiles enhance modern designs, from window frames to structural supports, offering strength and sustainability. - Automotive Innovation

Aluminium extrusions are critical to lightweight, durable components such as chassis elements and intricate interior designs. - Industrial Machinery

From conveyor systems to workstations, aluminium profiles ensure precision and reliability in machinery design. - Electronics and Technology

Lightweight and corrosion-resistant aluminium profiles are integral to casings, heat sinks, and structural components. - Renewable Energy

Extruded aluminium supports produce solar panel frames, wind turbine components, and other sustainable energy applications.

Why Choose Tuli Shop?

- Diverse Selection

Our extensive range of profiles includes T-slots, round profiles, and multi-channel options, catering to varied needs. - Customisation Options

We understand that every project is unique. With CNC precision cutting, we ensure your profiles match your exact specifications. - Quality You Can Trust

Each aluminium profile is rigorously tested to ensure precision-engineered solutions that exceed the highest quality standards.

Elevate Your Projects with Aluminum Extrusion

Whether you’re an architect, engineer, or hobbyist, the aluminium profiles at Tuli Shop empower your projects with unparalleled precision, versatility, and quality. Visit our online shop to explore our offerings and bring your vision to life.

(SPONSORED POST)