Production of aluminium metal by coal-based thermal energy causes a high emission level of almost 16 MT of CO2 per MT of metal produced. Reduction of CO2 emission will require either an alternative source of energy or efficient, stringent handling and management of the Electrolytic Cell for producing aluminium metal, in case the source of electrical energy is thermal power. Any reduction in the specific energy consumption would immediately reflect in the reduced CO2 emissions.

AI-powered optimisation of electrolytic cell variables

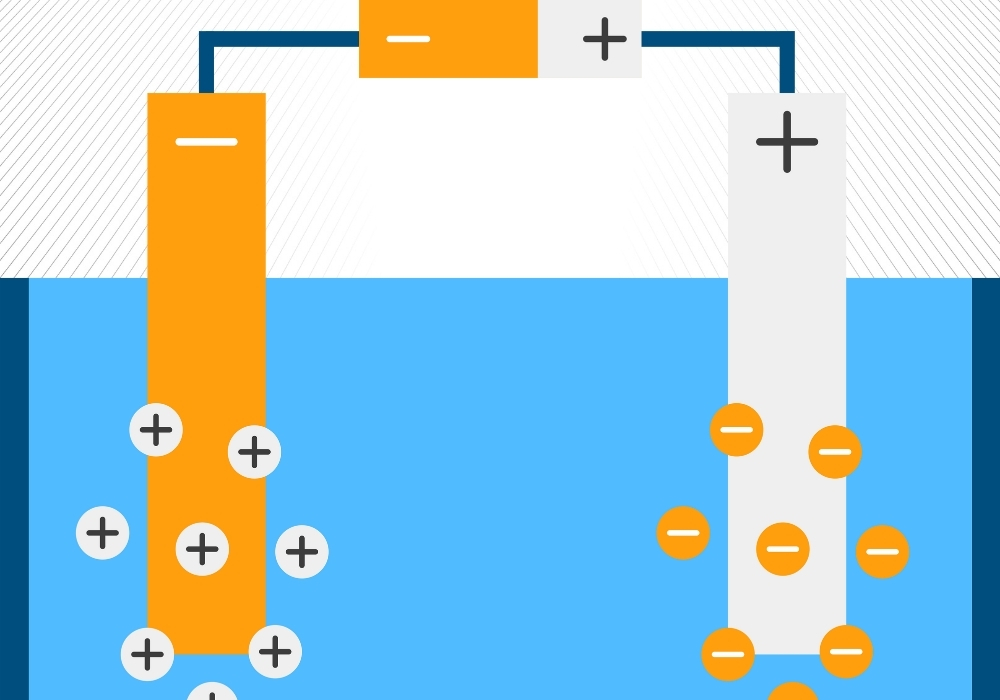

In Hall and Heroult’s process, variables like cell parameters consisting of bath temperature, current, alumina concentration and chemical composition of the melt are critical for achieving high current efficiency and minimum specific energy. It is required to be aware of the limiting conditions of different variables. No one can exceed inherent scientific fundamental laws governing the operation and therefore optimisation of those variables is the best possible executable action.

It is, however, important to understand the relationship between process variables and the resultant liquidus temperature, which can further be verified and utilised by a reliable AI/ML model. An effective model should utilise adequate training data for concentrations of Al2O3, Cryolite, AlF3 and CaF2. A collection of sufficient historical data to show convergence of predictive quantities against the observed ones is crucial to the successful deployment of the model.

Predictive control using neural networks

Predictive control using neural networks can be trained to predict the cell’s resistance and thus prevent adverse condition like anode effects which cause process instability and power fluctuations.

Machine learning models are used to predict the liquidus temperature of the cryolitic bath. This prediction and the thermodynamic phase equilibria condition need to be in agreement with each other. This helps to maintain the superheat, a critical factor for current efficiency and thermal stability. These models analyse vast quantities of real-time and historical data to operate the cells under the most energy-efficient conditions.

Anomaly detection by a reliable AI model to analyse and detect “noise patterns,” such as those indicating a short circuit or an improperly positioned anode, is another benefit one can expect. This allows for early corrective action, preventing major operational problems.

In conclusion, processes involving operational variables in electrolytic cells are possible to be predicted, and it is highly beneficial to maximise efficiency of the cell with minimum possible specific energy consumption and also optimum use of expensive raw materials.