The world has been undergoing electrification for the past 140 years. During the first 60 years, copper, a heavy metal, was used for electrical construction. It wasn’t the best conductor material because of its relatively low conductance per pound, but its abundance led to its exclusive use during the initial six decades of the electrical industry.

During that time, aluminium, a rare light metal, which has twice the weight conductivity of copper, was only available in small quantities. To get a feeling for what it was like at the beginning of the electrical industry in the 1880s, picture the Statue of Liberty, a gift from France to the United States in 1886, made of 200 thousand pounds of copper.

Figure 1: The Statue of Liberty in New York

At about the same time, the Washington Monument, erected to honour the first president of the United States, was completed with an aluminium cap weighing 100 ounces. That cap was then the largest aluminium casting in the world.

Figure 2: The Washington Monument in Washington, DC

During this initial chapter of electrification (1884-1944), everything that carried current was made with copper.

Figure 3: Early 1900s electrical distribution in New York

The electrical industry grew dramatically in the 20th century. Electricity became available everywhere in the United States. Regardless of time of day or where you were, you could flip a switch and the lights came on.

When power met water: How hydropower unlocked industrial aluminium

This electrical growth came to include the harnessing of hydro energy sources, which generated large amounts of electricity. Hydropower enabled the production process for making aluminium to switch from chemical to electrolytic reduction. Thus, after World War ll, aluminium began to be produced on an industrial scale.

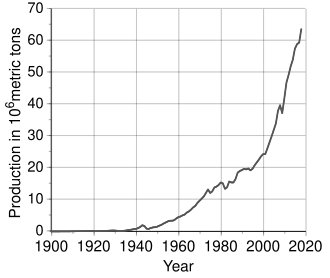

Figure 4: Global Production of Aluminium from 1900-2020

This flipped the copper-aluminium narrative: aluminium becomes plentiful and economical, while copper supply doesn’t grow as fast.

The post-war turning point: When aluminium overtook copper

Thus, in the second half of the 20th century, aluminium started to replace copper for carrying current. Within a period of two decades after World War II, electric utilities completely switched their lines from copper to aluminium.

Now in the 21st century, where the electrification of transportation, integration of renewable energy sources, bitcoin mining and growth of data centres are creating new challenges, the switch from copper to aluminium is additionally being driven by dramatically increasing copper prices.

From monopoly to competition: The end of copper’s exclusive reign

The electrical industry’s six-decade reliance on copper resulted in the “Copper: The Metal of Electrification” brand. Even though the monopoly is over and copper now competes with aluminium, people still think copper is best for all things electrical because the copper-electrical brand is so strong.

Change takes time, as the tendency is to continue what has worked in the past. The electrical industry can no longer afford to rely on the past if it is to meet the growing needs of the 21st century.

What the industry must now understand

The following is what one now needs to know about aluminium and copper:

Material Properties

- Aluminium has twice the weight conductivity of copper.

- Aluminium weighs just one-third as much as copper.

- One pound of aluminium provides the same current-carrying capacity as two pounds of copper.

Supply

- Aluminium production has increased tremendously since World War II. In just ten years, 1945-1955, aluminium production surpassed that of copper and continues to increase.

- Today, roughly three times more aluminium than copper is being produced. Aluminium is the third most abundant element in the Earth’s crust after oxygen and silicon.

- Copper prices are skyrocketing and are predicted to go higher because of constrained supply.

- The price ratio of copper to aluminium is now roughly four to one.

Bottom Line

- Aluminium now has an eight-to-one cost advantage over copper: $1 worth of aluminium provides the same electrical function as $8 copper.

- Aluminium is lightweight

- Aluminium prices are more stable than copper prices

- Aluminium is less prone to theft

Aluminium’s advantages are now so overwhelming that even tariffs cannot significantly change the aluminium-copper value proposition staring the global electrical industry in the face.

Conclusion

The electric switch has been flipped. It is a new “ball game” for the electrical industry. Antiquated standards, designs and ways of thinking about copper and aluminium are changing because the old way of doing business is unsustainable. Aluminium will increasingly be used to meet the electrification challenges of the 21st century.

It’s fascinating to see how material choices in electrification have evolved over the years. The fact that aluminum, despite being less common in the early years, has now come into the spotlight due to its weight-to-conductivity ratio really speaks to the ongoing shifts in the industry. I think as demand for more sustainable and lighter solutions grows, aluminum will continue to take on an even bigger role.