Introduction

Green aluminium production based on scrap melting is now essential in the aluminium market. Melting contaminated scrap can present quality, environmental and yield issues. The dross generated by this process is contaminated with carbon and tends to burn, even violently. This is a safety, environmental and economic problem. Thermised dross has virtually no value, because the dross combustion ends with the almost complete oxidation of the aluminium contained in it. In conclusion, preventing the ignition of the dross or stopping its thermisation brings multiple benefits.

Foundry Ecocer’s endothermic fluxes

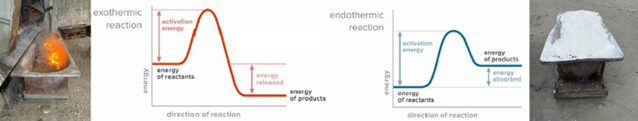

The oxidation of aluminium is a highly exothermic reaction, meaning it occurs with a significant release of heat; it can be considered a “combustion” in which aluminium acts as a fuel. The idea of Maurizio Sala, president and founder of Foundry Ecocer, was to use that heat to boost reactions that, from an energetic perspective, move in the opposite direction; these are “endothermic” reactions, which occur by absorbing energy. In this way, it is possible, within certain limits, to limit the temperature rise of the dross, preventing combustion from self-powering in an uncontrolled way.

This brilliant idea has resulted in several chemical formulations based on substances capable of endothermic reactions. Foundry Ecocer has specifically developed two categories of fluxes based on the same principle: fluxes that limit the ignition of dross inside the furnace and fluxes that stop the underway combustion of dross outside the furnace.

Also read: Global spotlight on aluminium dross: Who’s leading the dross production & aluminium recovery rate?

The first category includes Rockflux® 190, 191, 192 and 193, with progressively increasing degrees of endothermicity and produced in the form of Rockflux®, Foundry Ecocer’s typical and exclusive small tablets; the second category includes Foundry Quench 193 in powder form.

The reasons behind the adoption of two different forms for the two families of fluxes are as follows:

- Rockflux® fluxes are chemically more stable than granulates and powders, and therefore, the endothermic reaction can take place in the furnace for a longer time; vice versa, the powder shape provides the best covering power.

- Rockflux® is loaded into the furnace along with the scrap; the Foundry Quench is poured onto the burning dross when it is in the pots. This product forms a stable and homogeneous layer that isolates the dross from oxygen and, at the same time, reacts endothermically (and without emitting irritating fumes), leading to rapid quenching and cooling of the dross within a few hours.

In conclusion, Foundry Quench acts as a fire extinguisher, an additional safety for the operators who treat the dross.

Also read: Aluminium dross recovery and metal extraction: What to expect in 2025

L’approccio “endotermico” di Foundry Ecocer nella valorizzazione della scoria

Premessa

La produzione di alluminio green basata sulla fusione dei rottami è oggi il must del mercato dell’alluminio. La fusione dei rottami contaminati può presentare alcuni problemi di natura qualitativa, ambientale e di resa. La scoria generata da questo processo è contaminata da carbonio e presenta la tendenza a bruciare, anche violentemente. Questo aspetto rappresenta un problema di sicurezza e ambientale, ma anche economico. La scoria termitizzata ha infatti un valore pressoché nullo, in quanto la combustione della scoria termina con la quasi completa ossidazione dell’alluminio in essa contenuto. In conclusione, prevenire l’innesco della scoria o arrestarne il thermiting porta a molteplici vantaggi.

I flussi endotermici di Foundry Ecocer

L’ossidazione dell’alluminio è una reazione fortemente esotermica, avviene cioè con un notevole rilascio di calore; essa può essere considerata a tutti gli effetti come una “combustione” nella quale l’alluminio svolge il ruolo del combustibile. L’idea di Maurizio Sala, presidente e fondatore di Foundry Ecocer, è stata quella di impegnare quel calore per promuovere reazioni che, dal punto di vista energetico, si muovono nel senso opposto; si tratta di reazioni endotermiche, che si svolgono assorbendo energia; in questo modo è possibile, entro certi limiti, contenere l’innalzamento di temperatura della scoria, in modo che la combustione non sia più in grado di autoalimentarsi in modo incontrollato.

Questa idea brillante si è tradotta in alcune formulazioni chimiche, basate su sostanze in grado di reagire endotermicamente. Foundry Ecocer ha, nello specifico, sviluppato due categorie di flussi, basate sul medesimo principio: flussi in grado di limitare l’innesco della scoria all’interno del forno e flussi in grado di arrestare la combustione della scoria, già in atto, fuori dal forno.

Alla prima categoria appartengono il Rockflux® 190, 191, 192 e 193, con gradazioni di endotermia via via crescente e prodotti nella forma di Rockflux®, le caratteristiche ed esclusive mini-compresse di Foundry Ecocer; alla seconda categoria appartiene il Foundry Quench 193, in forma di polvere.

I motivi che hanno portato all’adozione di due differenti forme per le due famiglie di flussi sono i seguenti.

I flussi in forma di Rockflux® sono chimicamente più stabili dei granulati e delle polveri e dunque la reazione endotermica può svolgersi in forno per un tempo maggiore; viceversa, la polvere è la forma che assicura una maggiore capacità coprente.

I Rockflux® vengono caricati nel forno insieme al rottame; il Foundry Quench viene invece versato sulla scoria che brucia, quando questa è nelle casse. Questo prodotto è in grado di formare uno strato stabile e omogeneo, che isola la scoria dal contatto con l’ossigeno e che al contempo, reagendo endotermicamente (e senza emissione di fumi irritanti), porta alla rapida estinzione e al raffreddamento della scoria nel giro di poche ore.

In definitiva, il Foundry Quench fa da estintore, una sicurezza in più per gli operatori che trattano le scorie.