Ever since decarbonisation initiatives by the primary aluminium industrial players gained pace over the last couple of decades, the concept of an anode other than carbon to avoid emission of CO2 at the site of aluminium production has become an important strategic consideration.

How can inert anodes replace carbon?

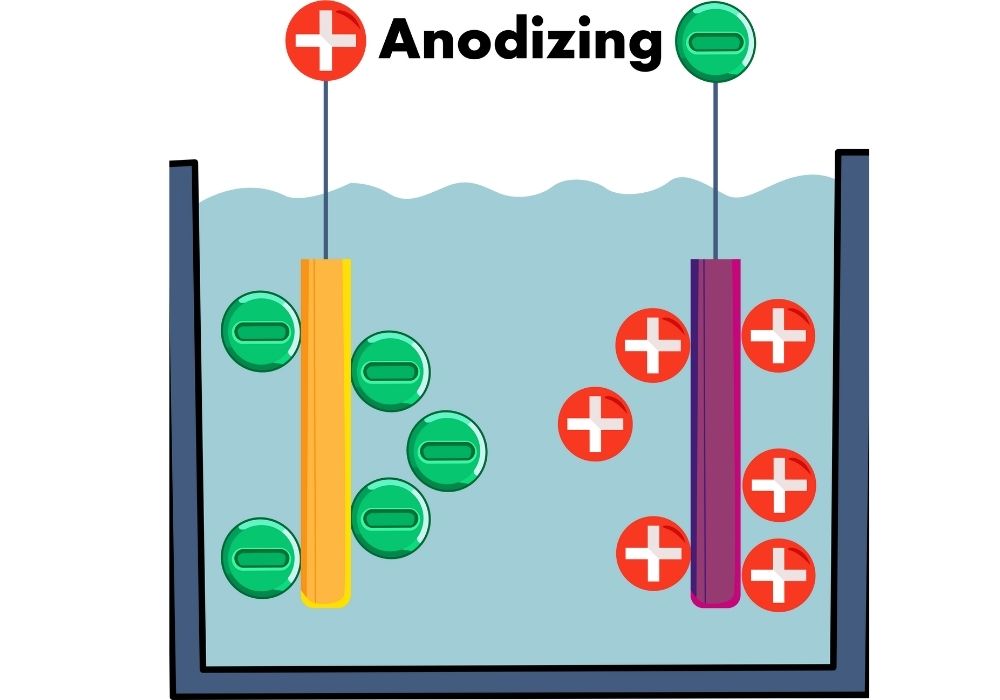

Inert anodes replace carbon in aluminium smelting, producing pure oxygen instead of CO2 and eliminating greenhouse gas emissions. The mechanism involves the electrolytic oxidation of oxide ions (from dissolved alumina) into oxygen gas at the inert anode’s surface, which does not react or get consumed in the process. This differs from traditional carbon anodes, which react with oxygen to form CO2 and are consumed.

Inert anodes in aluminium production cells have an increased theoretical cell voltage, around 2.2-2.3 V, compared to conventional cells (~1.2 V) due to the absence of the chemical energy from consumable carbon anodes, requiring 1 V more just for the electrolysis itself. Estimates suggest a potential 25% reduction from current levels to around 10 to 12 kWh/kg Al or even lower.

Concerning challenges of carbon anodes

However, there will be challenges for the use of carbon anodes. Actual operational voltage in the cell may be 1 V higher than the present scenario, which will actually require a higher specific energy consumption. This also signifies that the coal-based power plants will emit higher CO2.

There are other stiff challenges for using inert anodes, like restricted current density, resistance towards fluoridation, high electrical conductivity, high stability towards oxygen and most importantly of all, retrofitting of existing cells. Group of materials, to name a few, which have drawn attention for intense research and tests are oxides of Ni-Fe-Sn, Cermets, which are a combination of ceramics and metals and pure alloys of Cu-Fe-Ni. A very recent report by a major primary aluminium producer mentions that the industrial-scale trial for production of A7 grade aluminium equivalent P1020 has been accomplished successfully to establish the effectiveness of inert anodes for production of good-quality commercial-grade metal.

This grade of metal is suitable for casting alloys and electrical products, signifying huge advantages for automotive, aerospace and other industries.

However, the point I feel optimistic about is not merely the reduction of emissions of CO2; this initiative is pushing the technological barrier of cell design. The design modifications in the cell, which are also being considered and worked with high intensity, are minimising the anode-cathode distance and wettable cathode to achieve a contact angle of molten aluminium on the cathode. These design aspects have long been attempted; perhaps this is the right moment when disruption will be seen with all these clicking together. To conclude, production of green aluminium with much reduced specific energy requirement and higher recycled quantity will see the metal shining in components of aerospace, automotive, building and construction and marine.