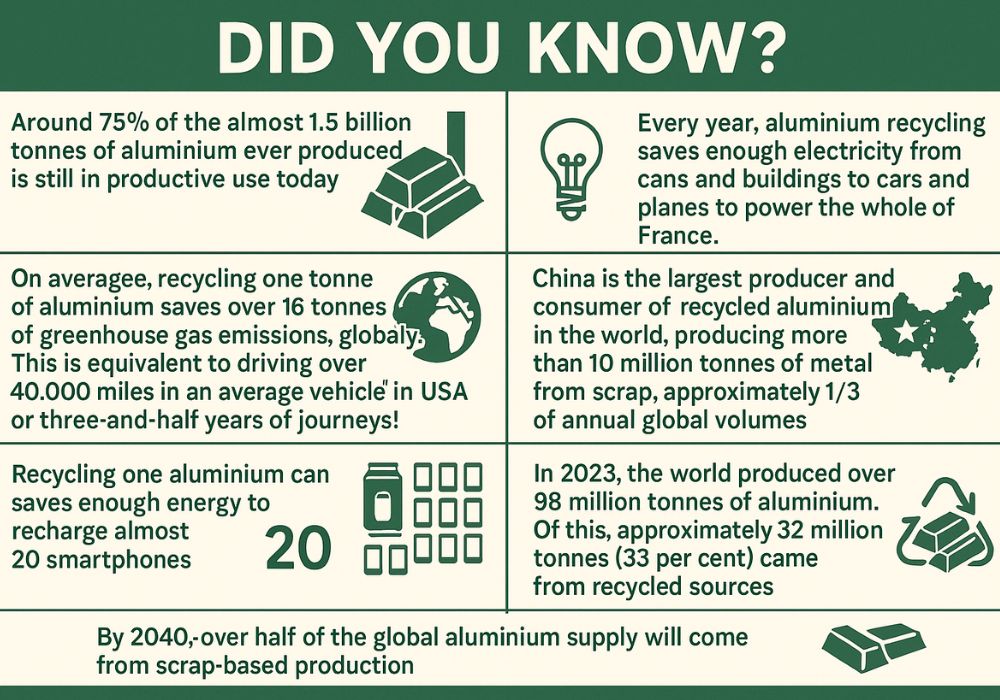

Aluminium doesn’t do goodbyes, it just keeps showing up. Melt it down, shape it up, and boom, it’s back again. Cans today, cars tomorrow and maybe skyscrapers next week! While other materials retire, aluminium just reinvents itself. Forget the old-school image of recycling as a chore. Aluminium recycling is a high-impact, low-effort solution to reducing energy use, cutting carbon emissions, and preserving the planet’s precious resources.

This makes it a standout material in the circular economy. As per the International Aluminium Institute (IAI), each year, over 30 million tonnes of aluminium scrap are recycled worldwide, reaffirming aluminium’s place as one of the most recycled materials on Earth. Infact, the global secondary aluminium market is expected to rise from USD 107.05 billion in 2023 to USD 160.81 billion by 2032, highlighting its pivotal role in driving the future of low-carbon manufacturing. In short, recycling sits at the heart of the circular economy.

It’s the blueprint for balancing progress with responsibility.

The energy savings are remarkable, as producing aluminium from recycled scrap requires only 5 per cent of the energy needed for primary production. As Environmental, Social, and Governance (ESG) standards gain traction, sectors like automotive, packaging, and construction are embracing recycled aluminium to cut Scope 3 emissions and meet evolving regulatory demands.

Infact, it also plays a vital role in keeping industries humming and people employed. According to the Aluminum Association, the recycling sector powers 60,000 jobs nearly 38 per cent of the entire US aluminium workforce.

However, there’s still work to be done, but aluminium recycling is already showing us the way forward. In today’s blog, we’ll explore some of the top initiatives or projects shaping the future of aluminium recycling, programs, technologies, and partnerships that are turning theory into action, and vision into impact. Let’s dig in –

Novelis unveils Ulsan Aluminum Recycling Centre

Novelis, the global frontrunner in sustainable aluminium solutions and the world’s largest aluminium recycler, has officially opened the Ulsan Aluminum Recycling Centre in South Korea. This cutting-edge facility is set to make a major dent in carbon emissions reducing them by an estimated 420,000 tonnes each year. That’s the climate equivalent of what nearly 19 million trees could absorb annually, based on an average of 22 kilograms of CO₂ per tree. With an impressive production capacity of 100,000 tonnes of low-carbon aluminium sheet ingot annually, the Ulsan facility strengthens the company’s position in delivering sustainable materials for industries ranging from automotive to packaging while helping drive global decarbonisation goals forward.

Neveah’s Ogun State recycling facility

Neveah Limited has officially kicked off operations at its state-of-the-art aluminium and copper recycling facility in Ogun State, marking a significant milestone in Nigeria’s push toward circular manufacturing. During its inaugural production run, the plant successfully delivered its first batch of aluminium ingots, achieving an impressive purity level of 85.1 per cent a strong testament to the company’s commitment to quality as it scales up output. The facility is set to produce ADC 12-grade aluminium ingots, catering to both domestic demand and export markets. Sourced from recycled aluminium scrap such as used car engine components and beverage cans the ingots will be shipped to destinations across Asia and beyond, reinforcing Neveah’s role in powering the global circular economy through sustainable metal solutions.

Boosting Minnesota’s green manufacturing footprint

Minnesota’s manufacturing sector is entering a new era, with EGA Spectro Alloys leading the charge. The company has completed a landmark $71 million expansion in Rosemount, featuring a cutting-edge aluminium recycling facility that signals a major leap forward for both the region and the nation’s aluminium supply chain. The 90,000-square-foot facility isn’t just a boost for business it’s a strategic win for sustainability and the circular economy. Now equipped to deliver up to 120 million pounds of high-quality recycled billets annually, Spectro has introduced its first new product line in over five decades a bold move that reinforces its commitment to innovation, resilience, and environmental stewardship.

Alupro & UKARI’s new pilot project

In a bold move to enhance post-consumer aerosol (PCR) recycling, a three-month pilot project was launched on 2 June across Solihull in the West Midlands, England. The initiative aims to better understand how aerosols are managed in household waste by closely examining kerbside collection data and recycling behaviours. Led by Alupro under the UK Aerosol Recycling Initiative (UKARI), and delivered in collaboration with SUEZ Recycling and Recovery UK, the project will involve a detailed analysis of fully comingled waste streams. This work will be carried out by Sherbourne Recycling, which operates one of the world’s most advanced materials recovery facilities.

Largest aluminium recycling plant in UAE – almost 50% completed

Emirates Global Aluminium (EGA) is taking a decisive step by constructing the nation’s largest aluminium recycling facility. Work on the project began on November 21, 2023, and as of May 13, 2025, EGA announced that construction is 50 per cent complete an impressive 42 days ahead of schedule. Set to become operational in 2026, the facility will have the capacity to recycle up to 170,000 tonnes of aluminium annually. By establishing the UAE’s first large-scale aluminium recycling plant, EGA is not only strengthening the nation’s economic resilience but also laying the foundation for a robust domestic circular economy.

Hydro hosts groundbreaking ceremony for its recycling plant in Torija

On Monday, March 17, Norwegian aluminium and renewable energy leader Norsk Hydro broke ground on its state-of-the-art recycling facility in Torija, Spain. The €180 million project marks a significant step in Hydro’s circular economy strategy, aimed at increasing the use of post-consumer aluminium scrap and expanding its portfolio of low-carbon aluminium solutions in Europe. Once operational in 2026, the Torija plant will produce up to 120,000 tonnes of extrusion ingots annually, recycling around 70,000 tonnes of post-consumer scrap using advanced sorting technologies and innovative production methods. The facility will create approximately 65 new jobs and, together with Hydro’s nearby Azuqueca plant, boost the company’s total recycled, low-carbon aluminium capacity to 200,000 tonnes per year.

Australia’s aluminium industry just got a little greener

In a powerful nod to the “Made in Australia” spirit, Capral, Rio Tinto, and Sims Metals have teamed up to launch a closed-loop aluminium recycling initiative in Queensland-an impressive step toward a cleaner, circular future. Capral’s Bremer Park facility will supply post-production aluminium scrap, which Sims Metals will then sort and process. That processed scrap will head to Rio Tinto’s Boyne Smelter in Gladstone, where it’ll be remelted into fresh aluminium. The journey comes full circle as the recycled aluminium expected to top 1,000 tonnes with a 20 per cent recycled content is sent back to Capral’s Bremer Park site for extrusion and manufacturing.

France powers ahead with first industrial-scale aluminium cable recycling project

In a landmark move for Europe’s energy transition and circular economy goals, French transmission system operator RTE (Réseau de Transport d’Électricité) and cable innovation leader Nexans have launched France’s first-ever industrial-scale aluminium recycling initiative for high and extra high-voltage power cables. Kicking off in 2024, this pioneering partnership showcases how circularity and decarbonisation can go hand in hand to reshape Europe’s energy infrastructure. The project will recycle approximately 600 metric tonnes of aluminium annually, delivering significant environmental gains by avoiding at least 400 metric tonnes of CO₂ emissions each year. The initiative plays a critical role in helping France meet its SDDR 2025 network development targets.

Quebec brews a greener future with Nespresso

Nespresso Canada, in partnership with Éco Entreprises Québec, is expanding its innovative ‘green bag’ coffee capsule recycling program to every municipality in Quebec. The initiative is designed to simplify recycling for consumers while aligning with Quebec’s updated extended producer responsibility (EPR) regulations. As the province modernizes its selective collection systems, Nespresso users can now place their used capsules in special green recycling bags available for free with every online order, at Nespresso boutiques, and through the Nespresso Club. With this move, Quebec becomes the second province in Canada, after Prince Edward Island, to adopt the green bag program province-wide. Nespresso ultimately plans to scale the initiative nationwide, reinforcing its commitment to sustainable coffee consumption across the country.

Conclusion

The momentum is clear – aluminium recycling is no longer a niche sustainability effort it’s a core industrial strategy and one that delivers economic, environmental, and social dividends. As technology advances, partnerships evolve, and policy frameworks mature, the future of aluminium is not just bright it’s brilliantly circular. The only thing aluminium doesn’t do is stop. So let’s keep the loop going.