In the ever-evolving world of materials engineering, hot-rolled aluminium coils are emerging as one of the most dynamic and strategically important products driving industrial growth worldwide. As industries, from automotive to infrastructure, accelerate their shift toward sustainable, lightweight and high-strength materials, hot-rolled aluminium is no longer just a supporting player; it’s a lead performer in the global market trends reshaping modern manufacturing.

The process behind the power

Hot rolling is more than just a metal forming process, it’s a transformation of potential. Aluminium ingots, slabs, or continuous-cast strips are heated above the recrystallisation temperature (typically around 1000°F) and passed through powerful rolling mills. This high-temperature deformation refines the metal’s grain structure, enhancing ductility, strength and surface quality.

From direct chill cast slabs to continuous-cast strips, aluminium undergoes a “breakdown” phase in reversing mills and is then further reduced in continuous hot mills. The result? A versatile product known as a hot band, ready for downstream processing into everything from automotive body sheets and structural panels to heavy-duty industrial components.

Global market trends: Aluminium’s rising heat

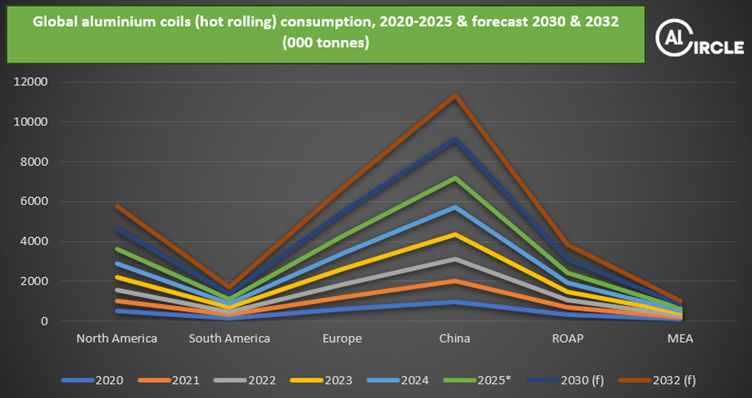

The global consumption of hot-rolled aluminium coils has been expanding steadily over the past decade, mirroring a wider industrial shift toward eco-efficient materials. The Asia-Pacific region, especially China, dominates consumption, driven by massive infrastructure investment, electric vehicle manufacturing and rapid urbanisation.

Source: AL Circle Research

Europe and North America follow closely, with growth supported by the automotive industry’s push for lightweighting, renewable energy installations, and green construction initiatives. Meanwhile, emerging markets in Southeast Asia, the Middle East, and Latin America are catching up fast, fuelled by expanding industrial bases and localised manufacturing capabilities.

A key insight from market trend research indicates that hot-rolled aluminium coils are increasingly displacing traditional steel products in applications where strength-to-weight ratio and corrosion resistance are decisive factors. This substitution is particularly visible in heavy transportation, shipbuilding, and large-scale structural systems.

Understanding market segmentation: Beyond one size fits all

To grasp the full scope of the hot-rolled aluminium coil market, it’s essential to look at different types of market segmentation. This segmentation helps manufacturers and investors understand where the most promising opportunities lie.

By end-use industry:

- Automotive & transportation – lightweight chassis, body panels and trailers.

- Construction & infrastructure – roofing sheets, bridges and facades.

- Machinery & equipment – pressure vessels, heat exchangers and industrial enclosures.

- Energy & electrical – renewable energy structures and transmission hardware.

By product type:

- Hot-rolled plates – thicker, heavy-duty applications.

- Hot-rolled coils – versatile for re-rolling into sheet or plate.

By region:

- Asia-Pacific including China leads production and consumption.

- Europe & North America drive innovation and technology upgrades.

- Middle East & Africa emerge as new frontiers of aluminium investment.

These layers of segmentation give market participants clarity on demand drivers, growth potential and evolving customer needs, an invaluable asset for both strategy and investment decisions.

Manufacturers marketing : Competing in a hot market

For producers of hot-rolled aluminium coils, success today requires more than production capacity, it demands smart, targeted manufacturers marketing. Leading players are now positioning themselves not merely as suppliers but as partners in innovation.

They’re leveraging sustainability certifications, digital marketing analytics, and customer co-development programs to differentiate themselves in an increasingly competitive landscape. Environmental performance, recycling efficiency and traceability are becoming key selling points, resonating strongly with automakers, builders and renewable energy companies seeking greener value chains.

Manufacturers are also investing in branding and technical communication, educating customers on the benefits of hot-rolled aluminium versus traditional materials, supported by robust data from market trend research and life-cycle assessments.

Outlook: Rolling toward sustainability

As the global economy transitions toward low-carbon production, aluminium coils (hot-rolled) will continue to gain momentum as a strategic material. The integration of renewable energy in smelting and casting operations, advancements in continuous rolling technologies, and circular economy initiatives will further strengthen aluminium’s green credentials.

In essence, the story of aluminium coils (hot-rolled) is one of innovation meeting sustainability, of manufacturers aligning with global market trends and of market segmentation strategies redefining how materials find their place in the modern industrial ecosystem.