In today’s fast-evolving aluminium industry, where sustainability goals are no longer a “nice-to-have” but an imperative, aluminium dross—once viewed as a hazardous substance—is fast becoming one of the most strategically valuable by-products in the global metals landscape.

AL Circle’s comprehensive industry-focused market research report, “Aluminium Dross Processing: A Global Review” peels back the layers of this transformation, offering unmatched insights into the technologies, players, regional dynamics, and market opportunities reshaping the dross narrative. Here’s why this report is more than just a read—it’s a roadmap to opportunity.

What is Aluminium Dross—and why should you care?

In the high-stakes world of aluminium production, one by-product has long been underestimated, underutilised, and often overlooked—aluminium dross.

Every time molten aluminium is handled—whether in smelters, recycling units, or downstream operations—it forms a crust-like layer called dross, rich in recoverable aluminium and other compounds. For decades, much of this material was discarded as waste, clogging landfills and costing the industry billions in lost metal and environmental fines.

But here’s the twist: aluminium dross is not waste. It’s an untapped resource—a potential goldmine of aluminium, salts, and oxides just waiting to be recovered with the right technology.

A global wake-up call: Dross generation on the rise

With global aluminium consumption climbing from 82 million tonnes in 2016 to over 100 million tonnes in 2024, which denotes that the production is even higher to some more million tonnes, the report notes a proportional surge in dross generation across all segments—primary smelting, secondary recycling, and downstream processing. An estimated 30% of dross still ends up in landfills, representing a massive untapped resource and a missed opportunity for sustainability-driven profits.

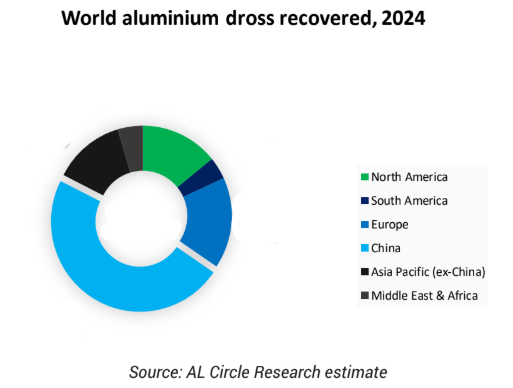

Asia Pacific (including China) is the world’s largest contributor to dross volumes—followed by Europe and North America. This geographical spread has important implications for recycling technology deployment, policy development, and cross-border trade.

Revolution in aluminium dross processing technology

One of the most exciting takeaways from the report is the evolution of dross processing technology. From rudimentary, energy-intensive techniques of the past to today’s proprietary, high-efficiency recovery systems, technological innovation is driving a shift in perception and practice.

Several suppliers now claim to recover 95% or more of residual aluminium from dross—a quantum leap from older recovery rates. The report highlights both on-site and off-site processing models, exploring their benefits, limitations, and adoption trends.

Need to compare dross recycling technologies or select the right vendor? Click here to get a comprehensive list of global suppliers, their capabilities, and the industries they serve. This makes it an essential tool for procurement professionals, operations managers, and technology investors.

From circular economy to strategic advantage

For sustainability leaders, aluminium dross recovery is more than waste management—it’s critical to closing the loop.

- Energy savings: Recycled aluminium uses just 5% of the energy required to produce primary aluminium.

- Carbon footprint: Processing dross instead of bauxite reduces greenhouse gas emissions, a key metric in ESG disclosures.

- Raw material efficiency: Dross recovery extends the life of mined resources and supports resource efficiency mandates worldwide.

Governments are also catching on. This study dives into policy and environmental frameworks around the globe, illustrating how tighter regulations are pushing aluminium producers toward integrated dross management systems.

Market Intelligence Backed by Hard Data

What sets this report apart is its data-rich approach. You’ll find:

- Dross generation volumes by region and sector

- Dross recovery rates in the primary, secondary, and downstream industries

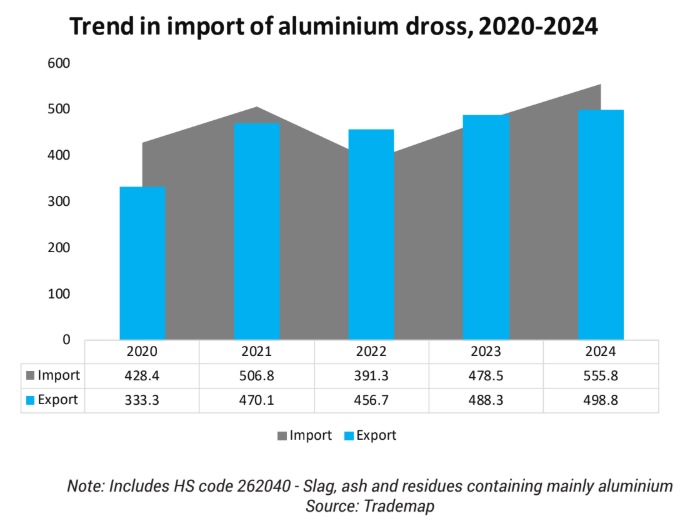

- Regional dross trade trends: imports, exports, and price dynamics

- Projections for 2025 & beyond: Generation, recovery, and aluminium extraction rates

- Real-world case studies from global dross processing projects

This is not generic commentary—it’s a data-driven blueprint for identifying profit zones and strategic gaps in your operations or investment strategy.

The Future is Clean, Profitable, and Dross-Driven

In a world where carbon neutrality, circularity, and ESG compliance are redefining industrial success, aluminium dross processing is no longer a backroom topic—it’s front and centre in boardroom strategies.

“Aluminium Dross Processing: A Global Review” is not just a report—it’s your ticket to understanding, participating in, and profiting from the green transformation of the aluminium industry.

Don’t just stay informed. Stay ahead. Subscribe to the report now and position your business at the forefront of sustainable innovation.