The history of aluminium is relatively short since it was discovered only in the nineteenth century, yet it has become an essential part of everyday life. Therefore, aluminium is an attractive material for many applications, including transportation, electrical, packaging and food industries, architecture, renewable energy production and batteries and it is also included in the critical raw materials list of many countries.

It is also a recyclable metal, which provides both environmental and economic advantages compared with primary aluminium smelting, which is an energy-intensive process in an energy-constrained world.

From a socio-cultural perspective, aluminium is considered a symbol of modernity and urbanisation.

From fiction to reality

When it comes to science fiction, especially when the relationship between science and science fiction is discussed, one of the first names that comes to mind is Jules Verne.

Jules Verne published his book “From Earth to the Moon” 160 years ago (1865), where the spacecraft that carried the ‘first astronauts‘ was made of aluminium.

The following dialogue occurs in the seventh chapter of the book:

“What is to be done, then?” said Elphinstone, with a puzzled air.

“Employ another metal instead of iron.”

“Copper?” said Morgan.

“No! that would be too heavy. I have better than that to offer.”

“What then?” asked the major.

“Aluminium!” replied Barbicane.

“Aluminium?” cried his three colleagues in chorus.

“Unquestionably, my friends. This valuable metal possesses the whiteness of silver, the indestructibility of gold, the tenacity of iron, the fusibility of copper, the lightness of glass. It is easily wrought, is very widely distributed, forming the base of most of the rocks, is three times lighter than iron and seems to have been created for the express purpose of furnishing us with the material for our projectile.”

“But, my dear president,” said the major, “is not the cost price of aluminium extremely high?”

“It was so at its first discovery, but it has fallen now to nine dollars a pound.”….

When Jules Verne devised his spacecraft with this singularity, it was only four decades since the Danish physicist Christian Oersted (1777-1851) had first extracted aluminium.

The revolution that started with the beer can: Recycling

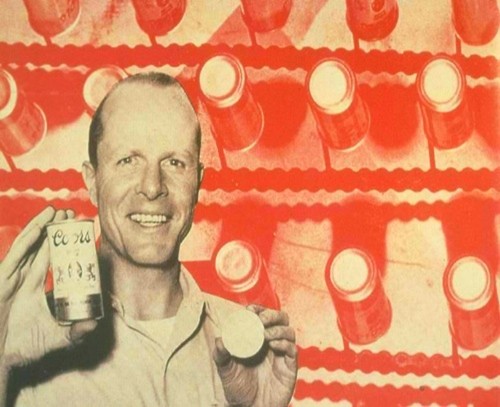

The recycling revolution began in the 1950s when Coors Brewing Co. introduced the aluminium can.

Before then, a can of beer meant a tin-lined steel container that affected the quality and flavour. Coors President Bill Coors became interested in aluminium as a better container because beer chills quickly in aluminium, it’s light and less expensive to transport and it doesn’t alter the taste.

And aluminium is 100 percent recyclable.

So, in 1959, Bill put Coors beer in a 7-ounce, two-piece recyclable aluminium can.

(source: www.molsoncoorsblog.com)

Recycling

Recycling pays multiple sustainability dividends:

- Avoiding greenhouse gas emissions counters the effects of climate change and also includes scope three emissions.

- Demonstrated energy conservation.

- Reduction of solid waste aids land conservation.

Considering other proposed methods (energy transition from fossil fuels to renewables, carbon capture and utilisation, hydrogen as an alternative fuel, etc.) to reduce global greenhouse gas emissions, recycling offers much more realistic solutions in the short term.

- A positive economic and social impacts to the community.

- Extends metal supply. Aluminium scrap becomes increasingly critical to downstream survival.

- Support domestic production in countries without local energy resources and/or raw materials (It became clear how important domestic production is during the pandemic).

- Industrialisation and sustainability of the industry will improve.

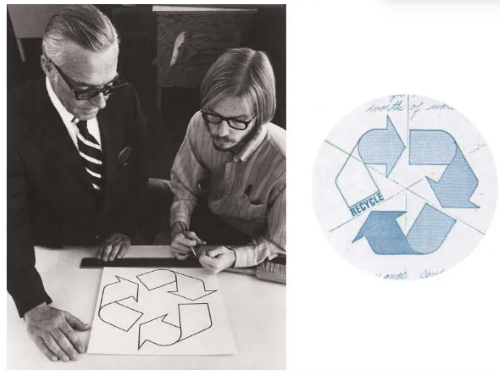

Bill Loyd and Gary Anderson designing the recycling symbol in 1970 (source www.recycling.com)

Magic Metal

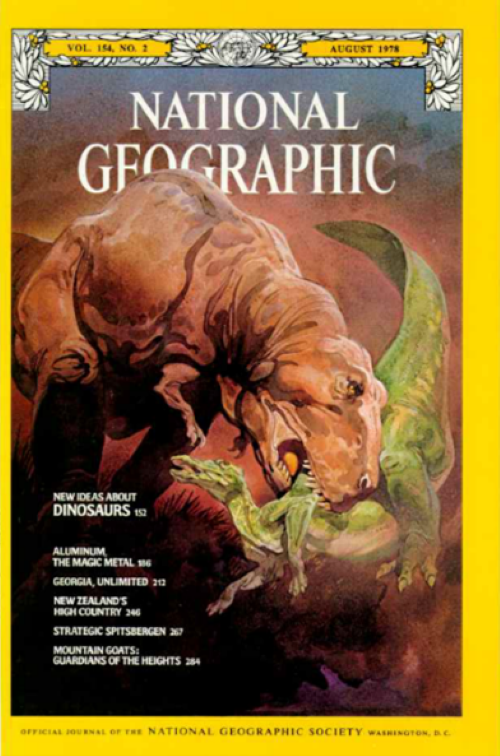

In the August 1978 issue of National Geographic magazine, Thomas Y. Canby published an article titled “Aluminum, the magic metal”.

I am sharing a few interesting sentences from Canby’s article below. These sentences also give clues about today’s recycling technologies.

“Indeed, just earlier ages of human development have taken their names from the distinctive material that nurtured them – Stone, Bronze, Iron – there are those who believe our era may be called the Aluminium Age.Cultural analyst Lewis Mumford observes that just as the industrial revolution transmuted “clumsy wooden machines into stronger and more accurate iron ones,” a task of today is “to translate heavy iron forms into lighter aluminium ones.”

“Recycling. How alluring the prospect, how elusive the goal. The litter and landfills of our throwaway society stand as a reproach to a way of life we know to be both wrong and immensely costly….”

“When we recycle aluminium, we save 95 percent of the energy needed to make new metal from bauxite. Once you make aluminium it becomes, in effect, an energy bank thay you can tap over and over again.”

“This energy saving makes scrap aluminium relatively valuable. And the largest single source is beverage cans.”

“Prospectors discover another bonanza in “urban ore” – the millions of tons of garbage that cities and counties struggle to sweep under that rug of countless landfills.”

“To hasten the day when this scrap becomes available, the big aluminium firms and other industries set up the National Centre for Resource Recovery in Washington, D.C., it’s head is dynamic Dr. Rocco Petrone, former director of the NASA Apollo program that put man on the moon.

“This is a complex technology,” said the burly engineers as we toured the centre’s pilot plant in Washington. “In mining refuse, we have to work with everything from banana peels to car axles. One thing that helps is the aluminium magnet.

Aluminium magnet? I knew that one property the magic metal lacks is magnetism.

“We set up a strong magnetic field,” explained Dr. Petrone. “When a nonmagnetic metal such as aluminium moves through the field, it is repelled – kicked aside. By placing a cluster of magnets alongside a conveyor belt in a recovery plant, we can kick the aluminium scrap right into containers.”

“Where will it all lead?

I frequently heard approval of the goal expressed by Nobel Prize-winning chemist Glenn T. Seaborg, former chairman of the Atomic Energy Commission. Dr. Seaborg envisions a society in which “the present materials situation is literally reversed; all waste and scrap – what are now called secondary materials – become our major resources and our natural, untapped resources become our backup supplies.”

“When and if this day comes, versatile aluminium will be playing a role – or maybe two or three.”

And that day has come!

The commercial use of aluminium started at the end of the nineteenth century and continues to grow today with the development of new advanced aluminium alloys, ever-increasing use of secondary materials and new areas of use by upgrading of post-consumer scrap to high-value-added products and finally closed the loop.

On the other hand, recycling is an ethical process from a technological perspective. Because primary aluminium production requires great capital and energy for mining, alumina production and electrolysis processes, increasing energy prices, problems in energy supply and the necessary cost for environmental protection will compound the difficulty of satisfying our future material needs.

This will require some changes in lifestyle as well as the development of appropriate new technologies: efficient vs inefficient use of materials, energy and the environment. In other words, it is the necessity to control the increase in entropy that occurs as a result of technological activities.