Introduction:

Industry 4.0 is a broad term used to denote the large-scale digitalization in an industrial environment using new-age technologies related to Automation, Artificial Intelligence & Machine Learning. The aim of integrating Industry 4.0 is to avoid human intervention & improve system efficiency by eliminating the chance of human error, which may occur due to repetitive jobs. Also, unlike humans, machines can be programmed to make better decisions in some scenarios, and in turn, human resources can be deployed in other creative areas.

The purpose of this article is to collect a brief idea about Industry 4.0 and the challenges in implementing Industry 4.0 technologies or solutions in aluminium smelters with special focus on developing economies like India.

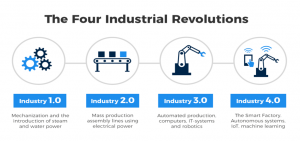

1) Industry 4.0: Overview

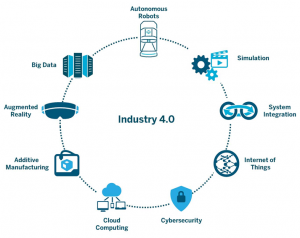

Digitization & automation are no newer to the industry but the pace at which it is going to change the industrial environment in the fourth industrial revolution is important, which is commonly referred as ‘Industry 4.0’. It refers to the machines which augment the work with wireless connectivity, artificial intelligence (AI), and machine learning along with the most advanced sensors enabling them to take the system decision independently, improving system efficiency. Digital systems & automation, along with the Internet of things and real-time data, have made Smart factory a reality. Although they are accompanied by many challenges but bring opportunities to materialize.

Although superior in many aspects, aluminium’s price point compared to steel gives it the most negative aspect as a substitute metal. But this, on the other hand, prompts the aluminium industry to go for automation to stay competitive in the metal sector. Most of the large-scale aluminium producers have started implementing Industry 4.0 in their factories worldwide, but India, for its cheap labour cost, will comparatively take more time for such adaption, particularly in already established setups. The implementation of Industry 4.0 will provide better safety & environmentally sustainable business operations as well as better control over process and reach to customers due to more accurate predictions & forecasts.

The key Industry 4.0 elements being deployed in Aluminium Industry are:

a) Digital production process & its control

b) Automation & Robotics

c) Big Data

d) Machine learning & Artificial Intelligence

e) Industrial Internet of things (IIoT) & Internet of things (IoT)

(IoT: it refers to computing concepts which connects everyday physical objects to the internet whereas IIoT refers to the use of sensors & actuators to support automation in the industrial set-up)

Fig 1 : Industrial revolutions & their importance

Fig 2: Industry 4.0 Technologies & Techniques

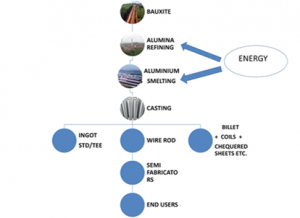

Fig 3: Positive impacts of I4.0 on the systems & processes

Fig 4: Examples of automated/Industry 4.0 based operations in the Aluminium Smelter

2) Challenges before Aluminium Smelters:

a. Retrofitting of the old smelters for enhancing efficiency/High cost of scaling:

Old smelters are at a disadvantage in terms of productivity per employee because of the smaller amperage technology. The latest smelters’ average productivity ranges from 240 to 260 tonnes per employee, whereas the older one has 110 to 180 tonnes per employee. But modernizing them is again a costly affair.

b. Recruitment policy changes, Up-skilling & training of the existing workforce:

The workforce for Industry 4.0 must have preliminary level of digital/computer literacy. So, it requires up-skilling /training of the existing workforce.

c. Handling of large-Scale waste generation:

Spent pot-lining (Debris of stopped electrolytic pot which contains poisonous material such as cyanides also and cannot be disposed, hence smelters are forced to store as high as 95% of it in covered areas)

Dross (General term is Slag):

Still recovery rate is very low, but it is improving with independent dross recycling plants coming up

Tapped bath which cannot be recycled and needs to be stored in an enclosed area

d. Implementation of Automation:

e. Implementing automation in existing set-ups require huge capital and may result in lay-offs to remain economically viable. Moreover, availability of cheap labour is the de-motivation for adopting new-age technology vehicles such as ‘Automated Guided Vehicles’ or AGVs, which require dedicated laser sensor-guided paths across the plant layout, unlike the existing, manually-operated technology vehicles.

f. Fear of Industrial relations problem due to lay-off in order to have economically viable business

g. Too many stakeholders: Promoters, peripheral villagers, land losers, employee union & association, Government and so on with lot of political interference.

h. Lack of trust & a fear of failure

i. Risks to data security:

It is because of data security many smelters still prefer to have their own servers for most of the technical operations, as hacking of the system if it is on the cloud will hit back severely, such as the one that happened with the NORSK HYDRO in the year 2019 leading to a loss of $300 million due to product imperfections.

j. Technology Disruption:

To date Hall-Heroult process is the most common process for producing aluminium by electrolytic reduction using carbon anodes, but with the recently installed test facility of the ‘ELYSIS’ technology, which uses inert anode, if successful in the coming five years will change the way the entire industry is functioning from supplier to end consumer. It will largely eliminate the supplier of carbon-based raw materials such as coke and coal tar pitch. Surprisingly, the process will become a net oxygen emitter instead of massive CFC emissions.

Challenges for implementation of Industry 4.0 solutions include:

(3.1) For Developing Economies:

a) Limited Infrastructure in terms of reliable internet connectivity in remote areas and lack of data storage facilities

b) Skilled workforce: It is a critical element; although India is trying to solve this through the ‘Skill India program’, but still a long way to go.

c) Demography: As a cheap labour workforce is available and a continuous pressure to generate employment, particularly for local people, automation sometimes takes a back seat unless very necessary, especially in the old smelters.

d) Cost of implementation: Implementing industry 4.0 solutions requires fresh investments in equipment, software & training cost, which is significant, particularly for old plants and more importantly, integration with existing systems is not easy.

e) Regulatory compliances: It requires significant changes in the regulatory framework & standards, which is a complex issue and harms where the system acts at a snail’s pace.

f) Resistance to change: The existing workforce will resist the change, and changing management is challenging to handle. Instead, it is viable to tell the current workforce the benefits of industry 4.0 implementation and the process of upskilling them to make them comfortably adopt the new system.

g) Security Concerns: The risk of cyberattacks cannot be ruled out & thus adequate protocols must be there to protect against such risks.

(3.2) For Developed economies:

a) High cost of implementation will lead to an increase in the production cost, which is already higher. But it can be balanced over the long run with reduced manpower cost.

b) Security concerns will also be there with developed economies as well.

3) Conclusion:

- Investment in automation would be a right step to reap its benefits in future.

- New Smelters are better positioned to apply Industry 4.0 concepts and get benefitted, but in whatever way possible, old smelters must be automated to remain competent & profitable.

- Successful implementation of Industry 4.0 technologies in aluminium smelters requires careful planning, investment, and a skilled workforce. While there are challenges in both the developing and developed economies, the potential future benefits of these technologies make the investment worthwhile.