Abstract

Like human being, each bauxite deposit is unique in its characteristics and requires thorough planning and systematic evaluation to optimise resources and grades. It is necessary to understand the short and long-term requirements of alumina refinery and accordingly target the grades, keeping in view the life of the mine. There should be strong coordination between mining and alumina refinery team and understand each other limitations and opportunities. In order to offset the high CAPEX of mining project, high grading can be resorted in the initial few years of operation and then slowly bring down the grades every year and adjust quality according to available resources and life of mine. The mine plan and quality control system should be formulated in such a way that a uniform quality of ore can be supplied for the whole year or given period. The maximum bauxite resources should be converted to mineable reserve by resorting to the best mining methodology, machine selection and dynamic cut-off grade (CoG). The present paper highlights the importance of bauxite deposit evaluation, grade-tonnage relationship, cut-off grade selection, quality control procedure and how to use all the resources without wasting valuable ore. A JORC complaint resources and grades serve a long-term objective of systematic evaluation, mining and define the life of mine.

1. Introduction

Bauxite deposits and resources are fast depleting, and it is necessary to systematically plan the exploitation of all the available grades and minimise the wastages at the mine site. Bauxite cut-off grade (CoG) should be planned in such a way that there is a minimum loss of bauxite value in the form of overburden. inter-burdens and so-called low grades/rejects. If necessary, simple physical beneficiation process should be adopted to bring down the silica content and increase the alumina values in so called rejects and low grades. Present paper mainly provides guidelines for the development of typical Eastern Ghats bauxite deposit of India and the importance of understanding the orebody configuration and cut-off grade for the optimisation of resources.

2. Laterite bauxite profile

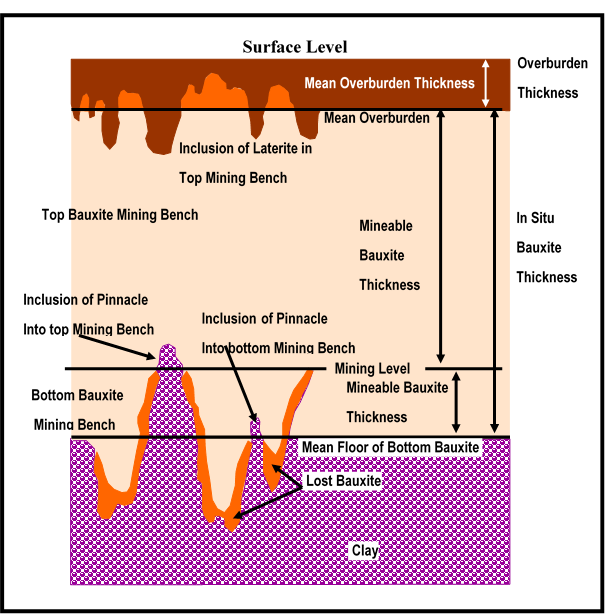

It is necessary to decipher the bauxite ore body configuration in the given deposit to understand the natural cut-off grade, which can be easily correlated with the geology of the deposit. The schematic diagram as given below shows the roof and floor relationship in the typical Eastern Ghats bauxite deposit for the identification of planned bauxite mining zones, the roof and floor of any deposits can have very complex geometry that can add to dilution during mining.

Fig.1 Configuration of ore body of typical Eastern Ghats bauxite deposit, India

Here the so called ferruginous-high silica overburden can be partly beneficiated by simple crushing-screening process and only top 50cm consisting of soil mixed with laterites boulders should be removed as waste. However, at places large topsoil / clay occurs and they should be completely eliminated and hard ferruginous laterites should be evaluated for blending with the high grades. In most of the high-level Odisha bauxite deposit, ore encounters clay rich parent rocks at the bottom, known as Kaolinised Khondalites (KK), where silica shoots up to 15 to 20% and this sudden transition can be identified as natural cut off point. At some places, high ferruginous laterites or Partially Laterised Khondalites (PLK) are also observed below the bauxite zone, which should be studied for possible inclusion in the ore zone with or without processing. As observed above, for Eastern Ghats bauxite deposits of India, silica becomes an important deciding parameter for the selection of CoG.

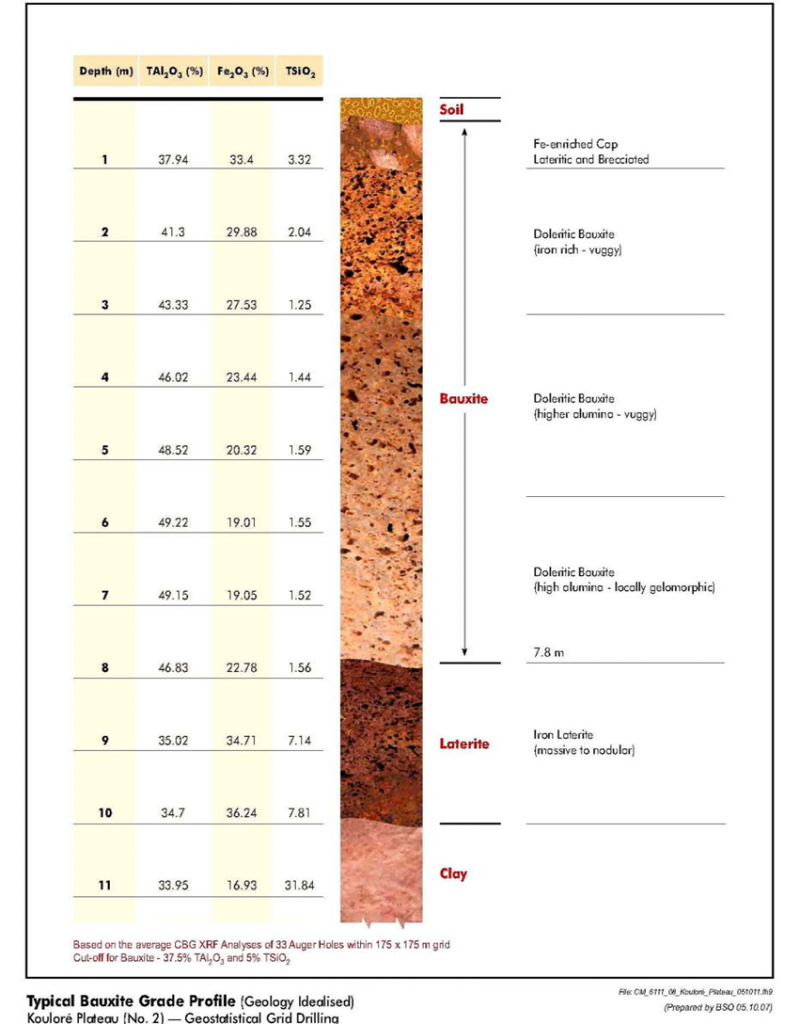

In case of lateritic bauxite of Guinea, silica is fairly low throughout the laterite-bauxite profile, however alumina drops at places, as shown below:

Fig.2 Laterite-Bauxite profile

Here alumina plays an important role in the delineation of orebody, therefore in most of the projects only alumina cut off was considered for ore resource estimation.

3. Relationship between resources and grade

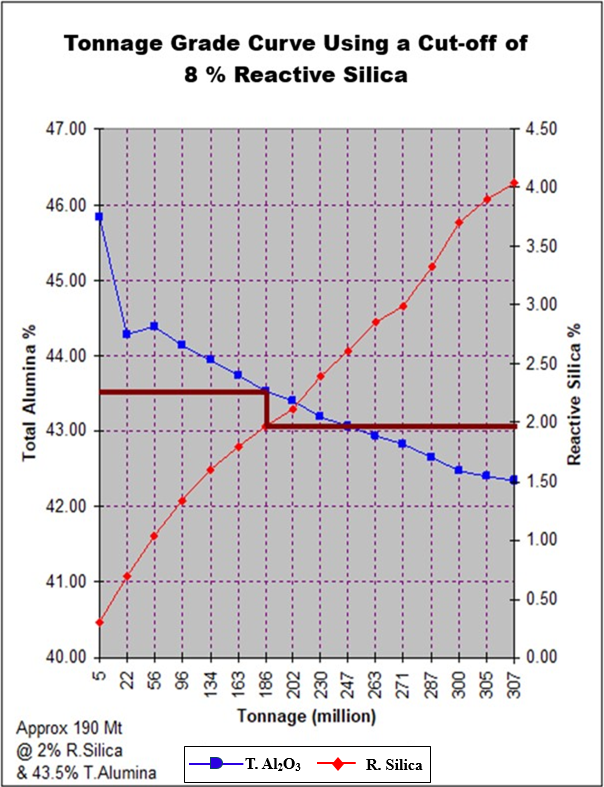

Bauxite resources are reported as tonnes and grade above a stipulated cut-off values of alumina and silica. As cut off value decreases, ore resources go up, however, there is a natural boundary below which there is sudden increase in silica and/or drop in alumina content. A typical grade-tonnage curve for one of the Eastern Ghats bauxite deposits of Odisha is shown below:

Fig.3 Tonnage-Grade Curve

Here total alumina (Al) and reactive silica (R.Si) contents are plotted against the bauxite reserve in one of the Odisha bauxite deposits at the 8% R. Si cut-off. At this CoG, the maximum R.Si is only 4.5% in the bauxite. This tonnage grade curve indicates that a larger resource may be exploited if a higher reactive silica product can be economically processed in the given plant. For example, the desired product grade of 2% R. Si indicates an in-situ tonnage of only 190 million tons (Mt) at 43.5% total alumina. If the plant is ready to accept bauxite with 4.5% R. Si and 40% Al2O3; the resources in the deposit may go up to 307Mt. Further it will be easier to mine this quality, thanks to continuous orebody and large ore thickness. There is also an opportunity to partly bring down the reactive silica content by simple dry beneficiation process, which may also enhance alumina value in the product.

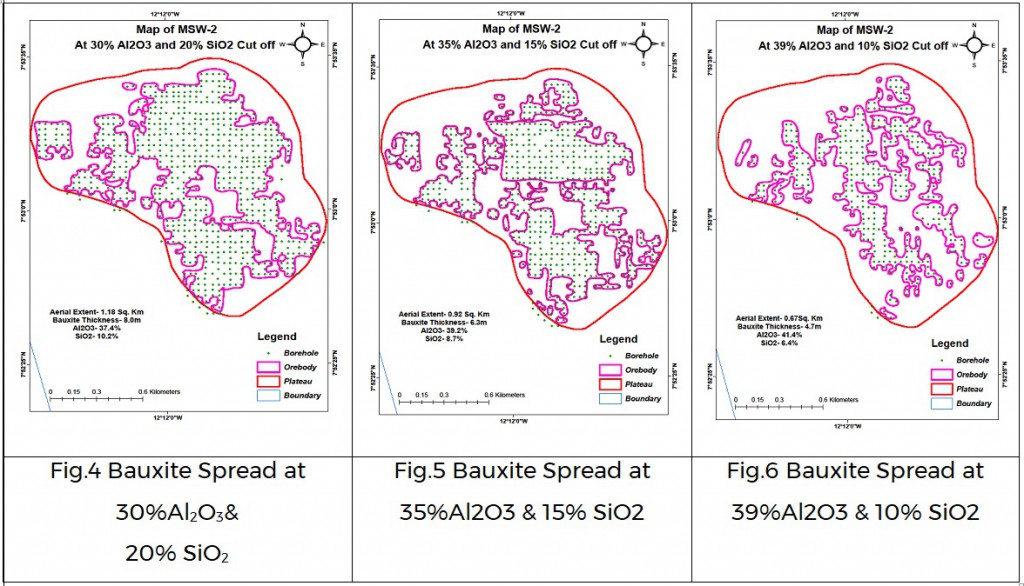

In order to demonstrate the geographical spread, bauxite thickness and grades at various CoG of alumina and silica is shown here for one of the bauxite deposits of Sierra Leone. Here three scenarios of ore disposition with increasing alumina and decreasing silica CoG are demonstrated as shown below.

As one can see here, the bauxite spread and ore thickness is slowly shrinking at higher CoG, however, the overall ore quality is continuously increasing. As this bauxite requires washing before the export, it is recommended to use the first scenario. The wet beneficiation process here yields one of the best quality washed ore, which is in general preferred by the low temperature alumina refineries.

4. CoG selection procedure

To decide the bauxite zone, only the silica content can be taken as the sole cut-off grade (CoG) criteria for Eastern Ghats bauxite deposits. To arrive at an optimum CoG for the given deposit, bauxite zones can be demarcated and resources / grades be estimated at 10 different SiO2% cut-off say 5 to 15% total silica. If found necessary, alumina cut off can also be introduced depending on the characteristics of individual deposit. After critical examination of resources and grades; 2-3 likely CoGs may be selected for the given deposit. At these selected CoGs, comparative alumina production cost can be estimated by simulating the given plant parameters and calculated raw materials consumption. Attempt should also be made to bring down the silica content by physical methods in the laboratory to check the amenability of the given bauxite to dry beneficiation processes. Discussions should be held with all the stake holders on resources and grades including the alumina refinery to suggest an optimum CoG for the given deposit. This optimum CoG should be thoroughly tested and positive/negative features should be highlighted and documented. At this cut-off grade, a series of sections, maps and plans can be generated to decipher the configuration of orebody. Based on the selected cut-off grade, various vertical domains in the lateritic bauxite profile such as top soil, hard cap (ferruginous laterites), bauxite, transition zone and lower KK and PLK zones can be identified and delineated for 3-D geological modelling.

5. Closed spaced drilling, variograms and 3-D geological model

It is necessary to carry out closed spaced drilling say 25mx25m or tighter grid in the selected 2-3 areas of about 300mx300m parcel of deposit to understand the short range variations in quality and ore thickness. These closed spaced drilling data are used in the preparation of variograms of alumina, silica and thickness and predict drilling grid pattern required for the Measured, Indicated and Inferred Resources. Variograms can highlight the grade variations for both Al2O3 and SiO2 at a local scale. These closed spaced drilling areas can be later on used for experimental mining either by drilling-blasting or using surface miner. Grade control drilling and mining/blending/stockpiling strategies are aimed at reducing this local grade variability to achieve proposed feed grade specification thresholds.

Three-dimensional (3D) geological models show the stratigraphic, structural and lithologic settings of the studied area in 3D space and serves as a 3D geodatabase for a variety of input data. The geologic and exploration database are the foundation of 3D modelling. These models provide a more realistic and comprehensive view of the subsurface geology compared to flat maps and cross-sections. In certain mines where blasting is required it can be used to optimize the pattern of blast by taking into consideration the pit geometry, nature of ore and rock mass, which helps to improve the efficiency of blasting and minimizes the waste generation. The model helps in selecting the most suitable mining equipment based on the characteristics of the deposit and the planned production rate.

6. JORC compliant bauxite resources

The JORC compliant mineral resources and ore reserves should satisfy some of the basic technical standards of survey, exploration drilling methodology, QAQC etc. Verifiable systems processes, databases, documentation of technical reports along with limitations certified by the competent person forms an integral part of JORC compliance report. Some of the basic requirements of JORC report are as follows:

- Survey manual providing procedure and showing survey control points on the deposit.

- Description of various types of drill machines used in bauxite exploration and diameter of holes to estimate recovery. For JORC compliance, borehole should have a minimum recovery rate of 80% depending on the geological conditions.

- In order to authenticate the primary drilling techniques, it is necessary to drill minimum of 10% of twin holes with diamond core drilling to check the results of primary exploration technique. Drilled holes should penetrate the whole depth of ore zone.

- It is also necessary to select block(s) for close spaced drilling say 25m x 25m to develop variograms of thickness, alumina and silica grades to establish horizontal and vertical variations.

- Prepare laterite bauxite profiles to understand the configuration of orebody and identify the major geological domains.

- Tonnage factor or density of various types of bauxite, laterites are to be determined by industry standard procedures and the same should be duly documented.

- Formulate sample preparation techniques for drill hole and pit samples.

- Analytical techniques and QAQC.

- Preparation and certification of Internal Bauxite Reference Materials (IRM)

- Preparation of bauxite analyses database for resource estimation.

- Prepare geological sections by adopting selected cut-off grade and develop 3-D geological model for resource estimation.

In order to achieve the certification, it is necessary to involve a JORC competent experienced person starting from the bauxite exploration work to resource-reserve estimation and mine planning stage. Evaluation of resources is a crucial and challenging task in every mineral exploration, irrespective of size, commodity, and deposit type and a reliable mineral resource estimate is critical to the success of every mining project.

7. Quality control system

Before the start of commercial mining, it is necessary to have a grade control drilling in the initial years of mining areas. This drilling may be carried out at 25mx25m grid or other grid pattern based on geostatistical analyses and it is also feasible to use vacuum suction drilling or down the hole (DTH) drill rig, which are also used for blasting purpose.

7.1 Bauxite mine

It is advisable to set up a simple bench top XRF at the mine site for day-to-day quality control as they are easy to calibrate with IRMs, requires simple sample preparation facility and easy to operate. The small XRF unit can determine the alumina, silica and iron content accurately and fast in the bauxite exploration samples, blast holes, mine faces and moving conveyer belts.

Fig.7 A typical bench top XRF

A comparative table of large and bench top XRF are given below:

| Sr.No. | Parameters | Big XRF | Table-Top XRF |

| Sample Preparation | Fused bead technique -costly process | Pellet press – simple operation | |

| Accuracy and Analysis | High accuracy with long suit analysis – mainly for research | Medium accuracy – requires good calibration with IRM. | |

| 3 | Cost with sample preparation facility | About US$300,000 | About US$125,000 |

| 4 | Main Application | R&D and high accuracy work | One type of ore and minerals at mining site |

| 5 | Operation Cost | Minimum US$10/ sample | About US$3 per sample |

Both big and bench top XRF require Thermal Analyser for LOI determination, which leads to about 100% bauxite analyses. Several tabletop XRF units are successfully working in various bauxite mining operation in worldwide projects.

7.2 Alumina refinery

The chemical and mineralogical composition of bauxite vary considerably, both within a mine and from mine to mine. The available alumina (A. Al) and reactive silica (R. Si) play a very important role in alumina productivity and plant efficiency. The conventional laboratory techniques to determine these basic quality parameters of bauxite is extremely time consuming and is not a solution for process control. The continuous automatic process control based on the real-time analysis data from the online analyser is the actual solution. The usual laboratory analysis of samples gives only an average grade over a long period of time. (depending on sampling frequency). Most often the laboratory analyses are available after the bauxite is already processed and has no relevance for process control actions. A. Al and R. Si are normally determined by bomb digestion by simulating the plant parameters. Process control in the continuous flow requires real time A. Al and R. Si data, mainly to adjust solid liquor ratio. The online analysers provide insight into the minute-by-minute variations and enable relevant process adjustments.

In the Bayer Process, one of the key process parameters is the alumina to caustic ratio (A/C ratio) at the back end of digestion, which should maximise the alumina recovery. Optimisation thus requires control of A/C ratio continuously in a preventive way, by knowing the bauxite quality going into the process. Quantification of the reactive silica also helps in estimating the necessary volume and concentration of caustic soda to be added, to ensure a sufficient digestion process.

At present three types of online bauxite analysers are available in the market – first is Near-Infrared Technology (NIR) technology of Spectraflow, second is controlled Neutron Activation (CNA) cross-belt analyses of Malvern Panalytical and third is laser based analytical technology of Lyncis company. Among them PFTNA (Pulsed fast and thermal neutron activation) is considered best as non-contact, non-destructive analytical technique that uses neutrons to determine the elemental composition of bulk raw materials.

8. Conclusions and recommendations

- As bauxite resources are fast depleting in the world, it is necessary to use so called overburdens, associated rejects, and low grades to conserve the valuable ore.

- Mining methodology of bauxite deposits, typically adopts concurrent reclamation therefore it is important to optimise the total resources and grade in collaboration with the refinery and through systematic exploration.

- It is important to understand the mode of bauxite occurrence, configuration of orebody and natural cut- off grade of the given deposit during the exploration work.

- The selection of optimum cut-off grade for the deposit is the vital step for delineating the orebody, predict grade and tonnage and likely rejects to be generated during mining. In some bauxite deposits, only silica or alumina cut-off grade is good enough, whereas in other deposits, require both constituents for CoG.

- For the JORC compliant bauxite resources, it is necessary to check the survey work, exploration technique, drilling recovery, sample preparation, analysis, QAQC and preparation of geological – exploration database.

- The identification of major geological domains in laterite-bauxite profile, variograms and 3-D geological modelling of orebody leads to resource estimation and its classification.

- It is recommended to set up simple bench top XRF at mine site, calibrate this with the internal reference samples for analysing large number of bauxite exploration and mining samples.

- An appropriate online bauxite analyser fitted in the conveyer belt of the process bauxite in the plant can provide real time analysis of bauxite samples, which helps in adjusting the solid – liquor ratio in the plant for the optimum digestion efficiency.

IBAAS-IIM 2024

International Bauxite, Alumina & Aluminium Society (IBAAS) is organizing 12th IBAAS Conference and Exhibition in Goa, India during September 25-27, 2024. The conference and exhibition will be held at BITS Pilani, Goa Campus, India. The theme of this year’s event, “Aluminium Industry – Vision 2030,” promises insightful discussions and innovative solutions shaping the future of the aluminium sector globally. Engage with industry experts, explore new processes, technologies, and forge invaluable connections with leaders in the field. Opportunities are available for sponsorship, exhibition and advertisements. A post conference visit to Belagavi alumina refinery is also organized for the interested delegates. For more details and updates please visit the IBAAS website http://www.ibaas.info/.

Author

Ashok Nandi, Ajit Sahu and Hiresh Shrirame

International Bauxite, Alumina and Aluminium Society (IBAAS)

Vedanta Aluminium