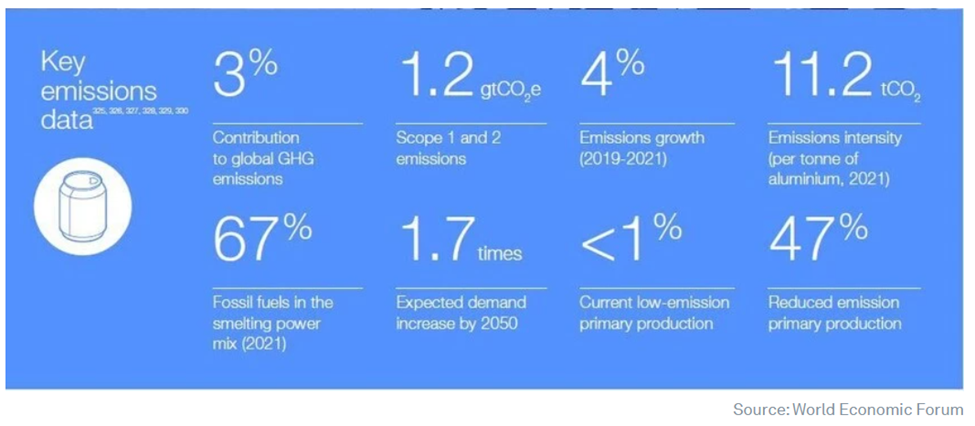

Aluminium is a chief raw material that supports the growth of various industries like construction, manufacturing, and transportation. Regrettably, aluminium production emits almost 270 Metric tonnes of carbon into the atmosphere, which contributes to 3% of the world’s direct industrial carbon emissions.1 Increasing carbon emissions has been creating a catastrophic impact on the global environment resulting in economies to prioritise net-zero targets. The UK government is already planning to achieve the net-zero target by 2050.2 Therefore, the aluminium production industry is making a shift to low-carbon aluminium.

Wondering what is low-carbon aluminium and how it will serve the Net-Zero purpose?

Read further to find out.

What is net-zero and why do we need to prioritise it?

The net-zero target is the priority of reducing Greenhouse Gas (GHG) emissions within a stipulated period to attain the global sustainability goals related to clean air and saving the environment. The concept of net-zero was first introduced by Professor Myles Allen in the late 2000s.3 Professor Allen presented that CO2 emissions must be balanced to reduce the impact of global warming. Excessive emissions of GHGs, specifically CO2, have been creating an environmental imbalance, resulting in global warming and climate change.

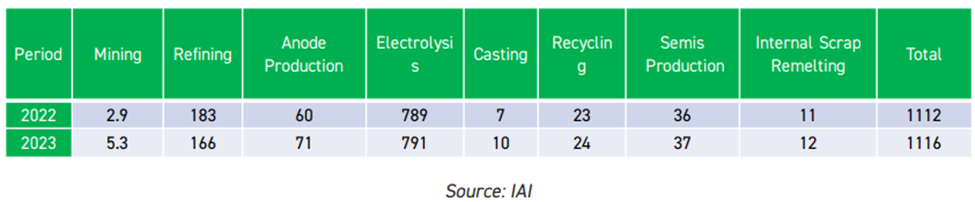

Global CO2e emissions of the aluminium industry in 2022-2023 (in million tonnes)

The concept of Net-Zero target aims to strike a balance between the production and removal of GHGs from the atmosphere. The continuous increase in GHG emissions has been accelerating the rate of climate change and global warming. As a consequence, net-zero emerged as a target for controlling and reducing emissions to ensure a sustainable planet.

How is net-zero affecting aluminium production?

Net-Zero aims to reduce GHG emissions through the use of clean power, recycling resources and utilisation of low-emission technologies. However, aluminium production is forecasted to decline at a rate of 4% per year to comply with Net-Zero requirements. Here are a few reasons why Net-Zero is negatively influencing aluminium production.

Reduced clean energy infrastructure: Aluminium production is energy-intensive as it uses 67% of the fossil fuels in smelting activities. Net-Zero requires a conversion to clean power or alternative energy for powering production facilities. Over-reliance on fossil fuels has been catastrophically reducing aluminium production to comply with Net-Zero targets. Furthermore, only 30% of clean power infrastructure exists globally, shrinking the chances of aluminium production with reduced reliance on traditional fuels.

Note: To reach net zero, the industry will need to increase use of clean power, improve the share of recycled aluminium and progress low-emission smelting and refining technologies.

Cost-intensive practice: Net-zero targets require production facilities to adopt low-emission technologies which are cost-intensive. Experts state that production costs of low-emission aluminium surges to a 40%4 increase to traditional methods. Furthermore, low-emission aluminium requires extensive technological infrastructure. An investment of $560 billion in infrastructure and a CapEx of around $200 billion will be required to alter the existing inert anode and low-emission smelting technologies by 2050. The investments will reduce the profitability of the aluminium producers, creating a backlog.

What is low-carbon aluminium?

Low-carbon aluminium is a type of aluminium that is either produced through utilisation of renewable energy sources or is aluminium that is recycled from end-of-life aluminium scrap. Low-carbon aluminium, also referred to as green aluminium, aims to reduce carbon emissions through reduced carbon smelting and reuse of aluminium scraps. The process leads to the sustainable production of aluminium while complying with the Net-Zero requirements.

How does low-carbon aluminium production help minimise GHG emissions?

Low-carbon aluminium production assimilates a variety of techniques and innovations to reduce GHG emissions while contributing to attaining net-zero targets. Here are a few tactics that low-carbon aluminium production involves for reducing environmental footprint.

Low-carbon aluminium smelting: An innovative technique of low-carbon smelting is adopted, unlike the traditional aluminium smelting process, while relying on renewable energy like solar and hydro power. The carbon footprint from extensive aluminium production is deflected through reduced reliance on fossil fuels to power the smelting process.

Circular economy model: A circular economy model is applied as a standard procedure for enhancing the production of low-carbon aluminium. The circular economy model was introduced in the late 20th century and aims at reducing waste and pollution effectively through utilisation and reuse. The production of low-carbon aluminium involves a closed-loop system that is initiated by recycling the end-of-life aluminium scrap. The strategy assists in reducing waste and resource dependency while eliminating GHG emissions to a certain extent.

The advent of innovative technologies has been fueling the production of low-carbon aluminium, but what about the cost constraint? Continue reading to find out.

Beating the cost constraint in producing low-carbon aluminium

The Lean manufacturing model, introduced in the 1950s, can be used for identifying and removing the different types of wastes associated with the production will definitely support in curbing costs. The lean model emphasises recycling the waste to reduce the costs of raw material procurement and energy required to turn the production process.

Recycling is a major component of a low-carbon aluminium production system. According to experts, producing green aluminium through recycling end-of-life aluminium scraps consumes 5% of the energy required to produce fresh aluminium. Along with reduced energy requirements, low-carbon aluminium production enables a reduction in resource dependency. Reduced resource dependency eliminates further costs associated with the purchase of raw materials to fuel production loops.

The way ahead: The future of low-carbon aluminium

Low-carbon aluminium has been encountering a steady rise in demand due to international regulatory pressure and escalating environmental concerns. An exponential growth in demand is forecasted from 26 million tonnes in 2021 to a whopping 62 million tonnes by 2030.5

Nevertheless, cost constraints have been sparking severe blows on the industry. Experts revealed that a shift to low-carbon production technology is already in place but a complete transition is yet to come. The current infrastructural constraints thudding with below 1% transportation6 infrastructure will bear severe challenges for the industry to attain net-zero by 2050.

The way ahead shows a technological and infrastructural revolution in the aluminium production lines, a shift from the traditional to a subtle sustainable practice. The sole aim will be to reduce GHG emissions and calibrate with the Net-Zero targets without falling apart in terms of profitability.