When you think about aluminium, the sleek cans, aircraft bodies, or smart electric car frames might come to mind. But there’s a hidden story behind all that shine — a by-product known as red mud. For every tonne of alumina produced, about 1.25 tonnes of this highly alkaline waste are left behind. With over 4 billion tonnes generated globally to date, red mud isn’t just a by-product — it’s a colossal environmental challenge.

But within this scarlet dilemma lies a silver (and sometimes rare earth) lining — if you know where to look.

What exactly is Red Mud?

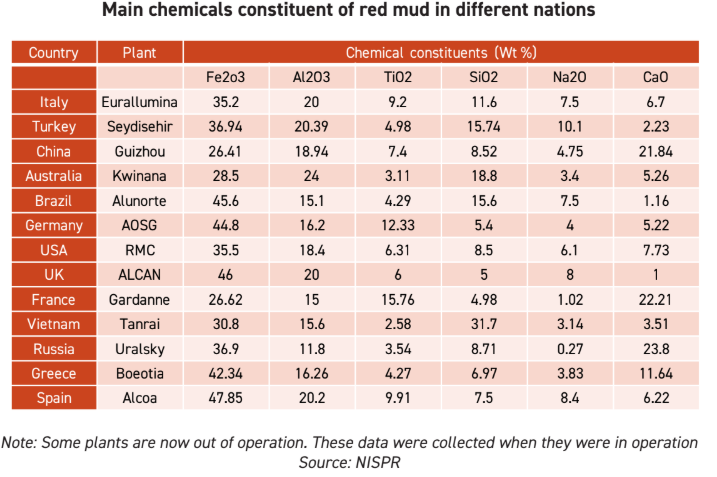

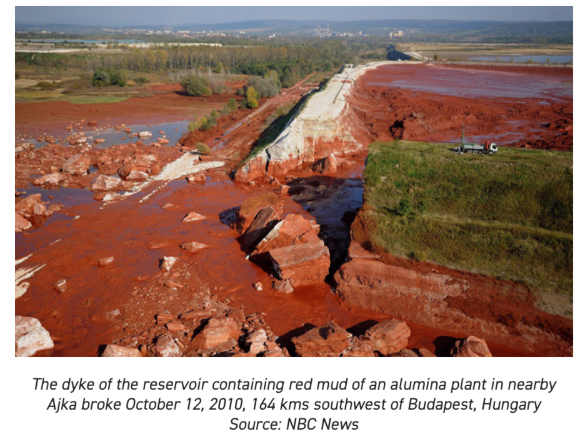

Red mud, also called bauxite residue, is what remains after extracting alumina from bauxite ore using the Bayer process. It’s a thick, caustic sludge packed with oxides of iron, aluminium, titanium, sodium, and rare earth elements. Historically, it was dumped into large ponds in slurry form, sometimes leading to severe consequences when containment systems failed.

In fact, the 2010 Ajka alumina refinery spill in Hungary, which released nearly 2 million cubic meters of red sludge, tragically underscored just how hazardous this material can be — ten lives lost, thousands impacted, and ecosystems scarred.

So why are we still generating millions of tonnes of it every year?

Red Mud generation — A global snapshot

From China to Brazil, India to Australia, alumina refineries are still pumping out red mud at alarming rates. The report details trends from 1974 to 2023, showing not just how much is generated — but where. China leads in absolute volume with rapidly expanding alumina capacities. Meanwhile, countries like Australia have moved towards more environmentally sound storage solutions like dry stacking.

The numbers don’t lie: from under 10 million tonnes in the early ’70s to well over 160 million tonnes annually today, red mud production is surging with aluminium demand.

Why Red Mud matters — And why it’s dangerous

Beyond sheer volume, red mud is problematic due to its chemical makeup. Highly alkaline (pH ~11.3), it can cause chemical burns on contact and leach toxic metals into soil and water if mismanaged. And once it dries, it can become airborne dust, posing risks to respiratory health — particularly in regions with strong winds and dry climates.

The good news? We’re getting smarter in how we handle it. Here is the report, which you should read.

Bright spots: Case studies in innovation

Several companies are pioneering new ways to tame — and even transform — red mud:

- EGA (UAE) has developed a method to convert red mud into manufactured soil, helping re-vegetate arid land.

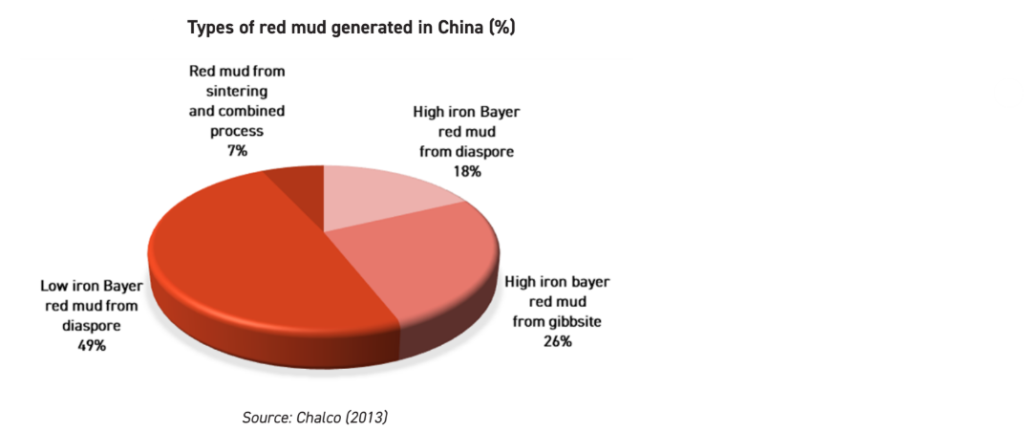

- CHALCO (China) implemented advanced dry stacking systems, reducing the footprint and risks associated with wet storage.

- Hydro Alunorte (Brazil) and partners are working to extract valuable minerals like scandium and titanium from red mud — turning waste into wealth.

- Alcoa has introduced press filtration at its Poços de Caldas refinery, recovering more water and creating drier, safer waste.

These examples offer a glimpse into a future where red mud isn’t a burden but a resource.

From liability to opportunity: Red Mud valorisation

The holy grail? Full valorisation — making red mud an asset rather than a liability. The report outlines several exciting prospects:

- Metal recovery: Through reductive smelting and acid leaching, red mud can yield iron, rare earths, and even aluminium.

- Construction materials: As a raw material for bricks, tiles, or cement, red mud has shown great promise, especially in developing economies.

China, in particular, has made strides in red mud utilisation, blending it into building materials and chemical industries. Yet globally, only a small fraction (less than 5%) of red mud is reused — the rest remains an environmental time bomb.

A wake-up call — and a roadmap

The report doesn’t just catalogue facts — it calls for action:

- Policy push: Stricter environmental norms and incentives can drive innovation in waste management.

- Technology transfer: Best practices from Australia or the UAE must spread to lagging regions.

- Research investment: Unlocking the full potential of red mud requires more R&D, particularly in mineral extraction technologies.

And perhaps most importantly, industry leaders, policymakers, and innovators must work together to reimagine red mud not as a toxic leftover — but as an untapped resource.

Want to know more?

This blog just scratches the surface. The full report, A Comprehensive Analysis of Bauxite Residue – Red Mud, is packed with:

- 10+ real-world case studies from global alumina producers

- Year-by-year data on red mud generation by country

- Technical insights into disposal technologies and valorisation techniques

- Future market and environmental impact forecasts

Subscribe now to unlock the full report — and gain insights that can shape strategy, sustainability, and investment decisions in the aluminium sector.

Don’t let red mud cloud the aluminium industry’s future. The solutions are here — if we choose to see them.