Why have not aluminium manufacturers taken advantage of the billions in opportunities in lightweight structure manufacturing? The reason is simple. They still believe in outdated myths related to aluminium alloys. So, what are these outdated myths? And how do we know they are debunked? Let’s start with the myths and then discuss how the solutions coming out of Innovative Weld Solutions dispel them.

The six aluminium alloy myths no one should believe anymore: Myth #1: Welded aluminium alloys are not good for fatigue (cyclic) loading applications Myth #2: Heat-treated aluminium alloys lose 50% of their strength in the weld heat-affected zones (HAZs) close to welds. Myth #3: Welded aluminium alloys are not effectively bake-hardened or used in dent-resistant applications. Myth #4: Thick-thin aluminium alloy structures with a thickness ratio greater than 1:3 cannot be welded with high quality. Myth #5: Aluminum alloy sheet metal cannot be resistance spot welded close to the edges of the sheets. Myth #6: Aluminum alloy sheet metal spot welds, such as those in automotive window panels, cannot be made to be cosmetically acceptable in a highly visible area. Now, onto the debunking. It’s based on welding technologies from Innovative Weld Solutions L.L.C.’s (IWSL), that effectively enable more widespread use of welded and lightweight aluminium structures enabling new paradigms. IWSL’s innovative and patented weld method uses large, water-cooled copper alloy electrodes that enable lowering the temperatures experienced by the weld HAZ during welding. This reduces the softening of the HAZ due to weld heat and significantly improves welded part strength and durability. Innovative tool design enables focusing the weld current on the intended weld joint location to create a high-quality weld nugget. How does this debunk those 6 obsolete myths? Let’s get into the specifics: Myth #1: Welded aluminium alloys are not good for fatigue (cyclic) loading applications

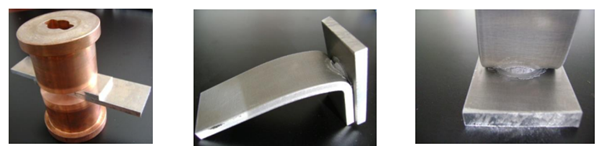

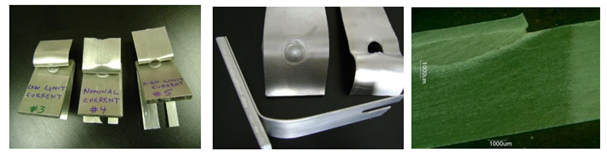

Figure 1. Large Water-cooled electrodes keep weld HAZs from overheating and softening. Peel-tested spot weld sample of 6.25 mm thick aluminium alloys shows a high-quality weld nugget with a break load of over 22000 Newtons. Given that, we call this weld a Focused-Melt Resistance Weld that enables strong aluminium structures – a Strong-AL FMRW™ weld. Figure 1 shows a typical large weld electrode set used to spot weld 6.25 mm thick aluminium alloy plates to one another along with a peel-tested welded part that shows a high-quality weld nugget. Figure 2 presents the fatigue test results of these spot welds and helps dispel Aluminum Alloy Myth #1. FMRW™ welded aluminium structures are proven to be good for fatigue-loading applications.

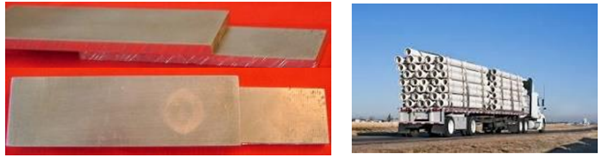

Figure 2. 6.25 mm thick 6061 T-6 alloy plate FMRWTM welded to a 6.25 mm thick 5454 H-34 alloy plate. These welds passed the fatigue test requirements of a flatbed manufacturer (0 to 1700 pounds (0 to 7561 Newtons) @ 1 cycle/sec for 30,000 cycles). These welds can effectively replace rivets in the manufacture of flatbed trucks shown on the right to improve costs and durability. Myth #2: Heat-treated aluminium alloys lose 50% of their strength in the weld heat-affected zones (HAZs) close to welds.

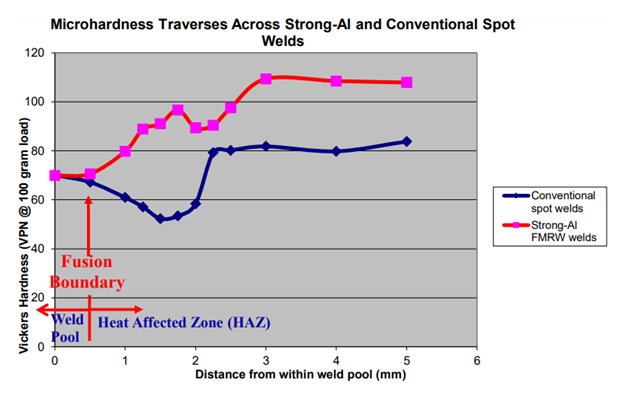

Figure 3. Typical Micro-hardness Traverses Across Conventional and Strong-Al FMRW™ Welds

Figure 3 shows typical micro-hardness traverses across cross-sections of conventional and Strong-Al FMRWTM spot welds. The softest region in the HAZ of a Strong-Al FMRW™ weld is seen to be nearly twice as hard (and consequently significantly stronger) as the softest region in the conventional spot weld. This key characteristic of a Strong-Al FMRWTM weld enables the dispelling of Aluminum Alloy Myth #2.

Myth #3: Welded aluminium alloys are not effectively bake-hardened or used in dent-resistant applications.

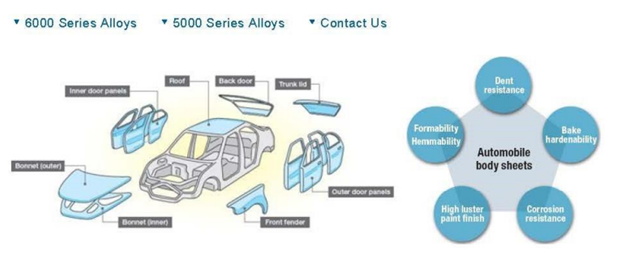

Figure 4. Typical Aluminum Alloy Sheets for automotive panels are shown on the website of the United Aluminum Company of Japan

(Ref. https://www.uacj.co.jp/english/products/sheeting/aas-panel.htm)

Figure 4 shows typical automotive aluminium panels and their applications. Conventional spot/arc welds of these alloy sheets adversely affect their suitability for “Dent Resistance” and “Bake Hardenability” applications due to excessive softening of the weld HAZ by these welding processes. The significantly higher hardness of the weld HAZ in Strong-Al FMRW™ welds enables their suitability for these “Dent Resistance” and “Bake Hardenability” applications, conveniently dispelling Aluminum Alloy Myth #3.

Myth #4: Thick-thin aluminium alloy structures with a thickness ratio greater than 1:3 cannot be welded with high quality.

Figure 5. Peel tested Strong-Al FMRW™ welds of Aluminum alloy 6061-T6 with a thickness ratio of 6:1. Peel tests are shown to result in satisfactory button-hole failures that show that the weld does not break. The Weld cross-section macrograph on the right shows a melted & solidified weld nugget and no overheating of the thin sheet welding. Common aluminium welding and weld design handbooks prohibit the spot welding of sheet metal with thickness ratios greater than 1:3 since it is very difficult to heat the thicker component sufficiently during welding due to its being a large heat sink. Figure 5 shows Strong-Al FMRW™ welds of thickness ratio 1:6. Peel test results and cross-section macrographs in the figure show excellent weld quality. Goodbye to Aluminum Alloy Myth # 4.

Myth #5 & Myth #6: Aluminium alloy sheet metal cannot be resistance spot welded close to the edges of the sheets; Aluminium alloy sheet metal spot welds, such as those in automotive window panels, cannot be made to be cosmetically acceptable in a highly visible area.

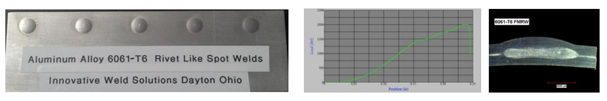

Figure 6. Cosmetic Strong-Al FMRW™ spot welds of Aluminum alloy 6061-T6 within 2 mm of the sheet edges. Welded part shows no weld metal expulsion or deformation at sheet edges. Shear test results show a ductile spot weld with an unusually high shear strength of 2050 pound-force (9118 Newtons). The cross-section macrograph shows a high-quality melted & solidified weld nugget and relatively cool outer surfaces that remain cosmetic. You know what that means – it’s the end of the road for Aluminum Alloy Myth #s 5 and 6 as well. V. (Anthony) Ananthanarayanan, Ph.D. President and Chief Technology Officer, Innovative Weld Solutions LLC and Distinguished Alumnus, Welding Engineering Program, The Ohio State University.

Email: anthony@innovativeweldsolutions.com