Aluminium extrusion stands out as a crucial process in creating intricate industrial structures and products. In the downstream aluminium segment, extrusions are used to make a myriad of useful applications for various end-user sectors. At the heart of this transformative method lies equipment specifically designed to turn solid aluminium billets into complex tailored profiles or other structures.

What is aluminium extrusion?

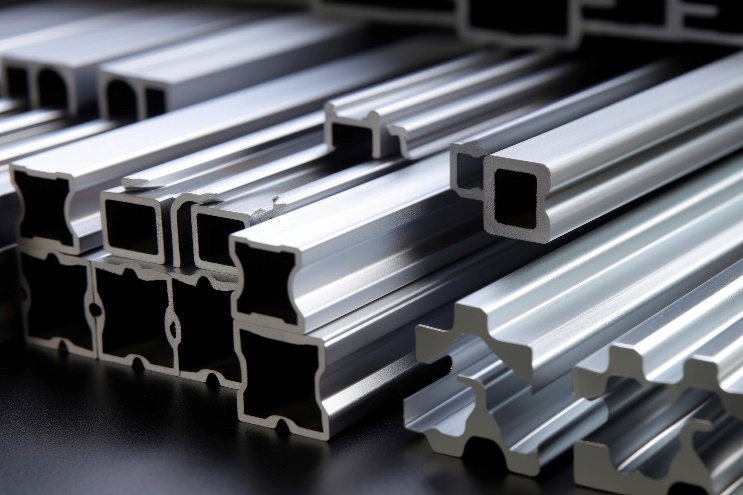

Aluminium extrusion is a manufacturing marvel that involves pushing aluminium alloys through a die to create customised cross-sectional profiles. As industries increasingly embrace the versatility of aluminium, the choice of extrusion machines becomes more important. These machines play a pivotal role in determining the extrusion process’s efficiency, precision, and overall success.

Let us explore the 5 kinds of macheries used to transform this malleable metal into essential components for various industries.

5 machines essential for aluminium extrusion production

1. Extrusion Press

The aluminium extrusion press is the workhorse of the extrusion process. It exerts immense pressure to transform heated aluminium billets into custom-shaped profiles. This hydraulic or mechanical press forces the material through a precisely designed die, resulting in intricate cross-sectional forms.

These presses ensure accuracy, efficiency, and consistency in producing aluminium components for sectors like construction, automotive, and aerospace. Reputed manufacturers like SMS Group, Presezzi Extrusion S.p.A., UBE Machinery Corp., etc., offer cutting-edge extrusion press solutions, ensuring precision and efficiency in shaping aluminium for diverse industrial applications.

2. Die

The aluminium extrusion die is the architect of transformation. It determines the final shape of extruded aluminium profiles. This custom-formed tool shapes molten metal as it passes through, defining the intricate cross-sectional design of the end product. An essential component in the extrusion process, the die’s accuracy and intricacy directly impacts the quality of the final output.

Leading manufacturers such as ECI, OMAV, and Alexandria Industries specialise in producing high-precision dies, pushing the boundaries of design possibilities in aluminium extrusion. As industries demand increasingly complex profiles, these dies stand as a testament to innovation, ensuring that the extruded aluminium meets the diverse needs of modern manufacturing.

3. Billet Heater

The billet heater is a vital player in the aluminium extrusion process. It serves as the gateway to the malleability of this metal. This machine preheats solid aluminium billets to an optimal temperature and enhances their ductility for the subsequent extrusion process. As the heated billet enters the extrusion press, it becomes more pliable, allowing for the precise shaping of complex profiles.

Manufacturers like Danieli Breda, Thermtronix, and CeraCon are at the forefront of billet heater technology, providing advanced temperature control and consistency solutions. In this critical step, the billet heater lays the foundation for the smooth transformation of aluminium into a diverse array of components.

4. Runout Table

The runout table is the silent guardian at the end of the aluminium extrusion process. It ensures the controlled cooling and stabilization of newly formed profiles. As extruded aluminium advances along this table, it undergoes a carefully managed cooling process to prevent distortion and guarantee uniformity. This crucial step is pivotal in maintaining the final product’s structural integrity and dimensional accuracy.

Leading manufacturers like Otto Junker, Presezzi Extrusion, and Danieli Automation specialize in cutting-edge runout table systems, contributing to the reliability of the aluminium extrusion process.

5. Cutter

The cutter table, a precision instrument in aluminium extrusion, adds the finishing touch to the process by accurately sectioning extruded aluminium into desired lengths. This machine ensures the uniformity and precision of the final profiles, meeting specific industrial requirements.

FOM Industrie, KMT Waterjet, and Elumatec are prominent manufacturers pioneering cutting-edge cutter technology. They offer solutions that enhance efficiency and accuracy. As the last step in the extrusion journey, the cutter table plays a crucial role in shaping the final product.

Shaping aluminium for industrial use – For a greener future

The growing demand for lightweight materials, including aluminium, is expected to persist as industries like transportation, construction, and packaging aim to diminish their environmental impact and enhance energy efficiency.

Computer-aided design (CAD) and 3D printing technologies will assist engineers in designing intricate aluminium profiles for various industries. Using such innovations, they will achieve exemplary efficiency in creating lighter and thinner prototypes. Also, recycling scrap in aluminium extrusion will add more sustainable choices to reduce the environmental footprint.

The use of Artificial Intelligence (AI), the cursor of Industry 4.0, will aid in understanding the material behaviour of this malleable metal. Analysing datasets will help extract behavioural insights to optimise extrusion processes.

By using evolved aluminium extrusion machines, new domains will open. For instance, creating lighter aluminium profiles will find application in developing renewable energy machines, electric vehicles, aerospace, etc. With advancements in cutting-edge technology, these machines contribute to the versatility and adaptability of aluminium extrusion products across diverse industries.